Self-lubricated Brass Alloy Bushings SPB

SPB

Brass alloy with embedded solid lubricant bushing is to open cavities of appropriate size and orderly arrangement on the metal friction surface of the bushing matrix. It was embedded a molded solid lubricant with unique self-lubricating properties in the cavities (the solid lubricant area is generally 25% - 35% of the friction area) and made of self-lubricating bushings.

It has been used in metallurgy of continuous casting machine, rolling equipment, mining machinery, shipbuilding, gas turbines and other high temperature, high load, low speed heavy load and other occasions.

Material

High Tensile Brass Alloy + Graphite Solid Lubricant Embedded

Features List

- May work without any oil for a long period.

- Extremely high load capacity, good anti-wear and lower friction

- Particularly appropriate for low speed and high load.

- Suitable for reciprocating, oscillating or intermittent motion where oil film is hard to be formed.

- Good chemical resistant and anti-corrosion characteristics.

- Can be used in wide range of temperature from -40°C - +300°C.

- Low maintenance frequency.

Technical Data

| Materia | CuZn24AL6 |

| Hardness | HB230-270 |

| Coefficient of Friction (µ) | < 0.16 |

| Max. Temp. | 300°C |

| Max. Dynamic Load | 100 N/mm² |

| Max. Speed (Dry) | 0.4 m/s |

| Max. Speed (Lubrication) | 5 m/s |

| PV Limit | 3.8 N/mm² *m/s |

Chemical Compositions

| Chemical Compositions % | ||||||||

|---|---|---|---|---|---|---|---|---|

| Cu | Zn | Al | Fe | Mn | Si | Ni | Sn | Pb |

| 64.24 | 25.10 | 5.17 | 2.67 | 2.82 | < 0.1 | < 0.5 | < 0.2 | < 0.2 |

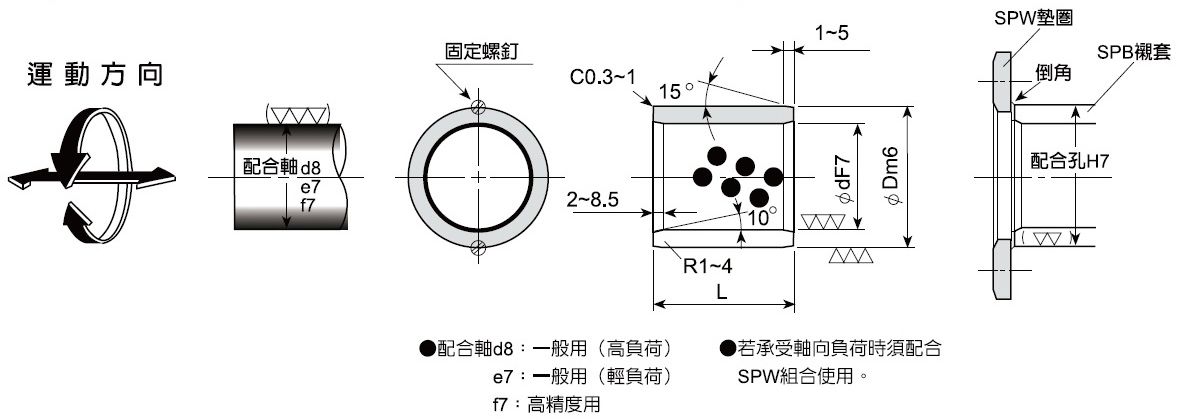

Drawing

SPB

Self-lubricated Bushings #500SP (SPB).

For rotation, swing and reciprocating motion.

ITEM NO=SPB-XX XX XX

ID OD Length

| Shaft diameter | Dimension (mm) | Length Tolerance | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | 8 | 10 | 12 | 15 | 16 | 20 | 25 | 30 | 35 | |||

| Ød | TOL | ØD | TOL | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | |

| 8 | 8 | +0.028 | 12 | +0.018 | -0.81208 | -081210 | -081212 | -081215 | |||||

| +0.013 | +0.007 | ||||||||||||

| 10 | 10 | 14 | -101408 | -101410 | -101412 | -101415 | -101420 | ||||||

| 12 | 12 | +0.034 | 18 | -121808 | -121810 | -121812 | -121815 | -121816 | -121820 | -121825 | -121830 | ||

| +0.016 | |||||||||||||

| 13 | 13 | 19 | +0.021 | -131910 | -131912 | -131915 | -131920 | ||||||

| +0.008 | |||||||||||||

| 14 | 14 | 20 | -142010 | -142012 | -142015 | -142020 | -142025 | -142030 | |||||

| 15 | 15 | 21 | -152110 | -152112 | -152115 | -152116 | -152120 | -152125 | -152130 | ||||

| 16 | 16 | 22 | -162210 | -162212 | -162215 | -162216 | -162220 | -162225 | -162230 | -162235 | |||

| 18 | 18 | 24 | -182412 | -182415 | -182416 | -182420 | -182425 | -182430 | |||||

| 20 | 20 | +0.041 | 28 | -202810 | -202812 | -202815 | -202816 | -202820 | -202825 | -202830 | -202835 | ||

| +0.02 | |||||||||||||

| 20 | 30 | -203016 | -203020 | -203025 | -203030 | -203035 | |||||||

| 25 | 25 | 33 | +0.025 | -253312 | -253315 | -253316 | -253320 | -253325 | -253330 | -253335 | |||

| +0.009 | |||||||||||||

| 25 | 35 | -253512 | -253515 | -253516 | -253520 | -253525 | -253530 | -253535 | |||||

| 30 | 30 | 38 | -303812 | -303815 | -303820 | -303825 | -303830 | -303835 | |||||

| 30 | 40 | -304012 | -304015 | -304020 | -304025 | -304030 | -304035 | ||||||

| 31.5 | 31.5 | +0.05 | 40 | -314030 | |||||||||

| +0.025 | |||||||||||||

| 35 | 35 | 44 | -354425 | -354430 | -354435 | ||||||||

| 35 | 45 | -354520 | -354525 | -354530 | -354535 | ||||||||

| 40 | 40 | 50 | -405015 | -405020 | -405025 | -405030 | -405035 | ||||||

| 40 | 55 | +0.03 | -405530 | -405535 | |||||||||

| +0.011 | |||||||||||||

| 45 | 45 | 55 | -455530 | -455535 | |||||||||

| 45 | 56 | -455630 | -455635 | ||||||||||

| 45 | 60 | -456030 | -456035 | ||||||||||

| 50 | 50 | 60 | -506020 | -506030 | -506035 | ||||||||

| 50 | 62 | -506230 | -506235 | ||||||||||

| 50 | 65 | -506530 | |||||||||||

| 55 | 55 | +0.06 | 70 | -557030 | -557035 | ||||||||

| +0.03 | |||||||||||||

| 60 | 60 | 74 | -607430 | -607435 | |||||||||

| 60 | 75 | -607530 | -607535 | ||||||||||

| 63 | 63 | 75 | |||||||||||

| 65 | 65 | 80 | |||||||||||

| 70 | 70 | 85 | +0.035 | -708530 | -708535 | ||||||||

| +0.013 | |||||||||||||

| 70 | 90 | ||||||||||||

| 75 | 75 | 90 | |||||||||||

| 75 | 95 | ||||||||||||

| 80 | 80 | 96 | |||||||||||

| 80 | 100 | ||||||||||||

| 90 | 90 | +0.071 | 110 | ||||||||||

| +0.036 | |||||||||||||

| 100 | 100 | 120 | |||||||||||

| 110 | 110 | 130 | +0.04 | ||||||||||

| +0.015 | |||||||||||||

| 120 | 120 | 140 | |||||||||||

| 125 | 125 | +0.083 | 145 | ||||||||||

| +0.043 | |||||||||||||

| 130 | 130 | 150 | |||||||||||

| 140 | 140 | 160 | |||||||||||

| 150 | 150 | 170 | |||||||||||

| 160 | 160 | 180 | |||||||||||

| Shaft diameter | Length Tolerance | ID | OD | Mating washer SPW | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 50 | 60 | 70 | 80 | 100 | 120 | 130 | 140 | 150 | ||||

| SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | SPB | ||||

| 8 | 8 | 12 | ------ | ||||||||||

| 10 | 10 | 14 | -1003 | ||||||||||

| 12 | 12 | 18 | -1203 | ||||||||||

| 13 | 13 | 19 | -1303 | ||||||||||

| 14 | 14 | 20 | -1403 | ||||||||||

| 15 | 15 | 21 | -1503 | ||||||||||

| 16 | -162240 | 16 | 22 | -1603 | |||||||||

| 18 | 18 | 24 | -1803 | ||||||||||

| 20 | -202840 | -202850 | 20 | 28 | -2005 | ||||||||

| -203040 | 20 | 30 | " | ||||||||||

| 25 | -253340 | -253350 | -253360 | 25 | 33 | -2505 | |||||||

| -253540 | -253550 | 25 | 35 | " | |||||||||

| 30 | -303840 | -303850 | -303860 | 30 | 38 | -3005 | |||||||

| -304040 | -304050 | -304060 | 30 | 40 | " | ||||||||

| 31.5 | -314040 | 31.5 | 40 | ------ | |||||||||

| 35 | -354440 | -354450 | -354460 | 35 | 44 | -3505 | |||||||

| -354540 | -354550 | -354560 | 35 | 45 | " | ||||||||

| 40 | -405040 | -405050 | -405060 | -405070 | -405080 | 40 | 50 | -4007 | |||||

| -405540 | -405550 | -405560 | 40 | 55 | " | ||||||||

| 45 | -455540 | -455550 | -455560 | 45 | 55 | -4507 | |||||||

| -455640 | -455650 | -455660 | 45 | 56 | " | ||||||||

| -456040 | -456050 | -456060 | -456070 | -456080 | 45 | 60 | " | ||||||

| 50 | -506040 | -506050 | -506060 | -506070 | -506080 | 50 | 60 | -5008 | |||||

| -506240 | -506250 | -506260 | -506270 | 50 | 62 | " | |||||||

| -506540 | -506550 | -506560 | -506570 | -506580 | -5065100 | 50 | 65 | " | |||||

| 55 | -557040 | -557050 | -557060 | -557070 | 55 | 70 | -5508 | ||||||

| 60 | -607440 | -607450 | -607460 | -607470 | -607480 | 60 | 74 | -6008 | |||||

| -607540 | -607550 | -607560 | -607570 | -607580 | -6075100 | 60 | 75 | " | |||||

| 63 | -637560 | -637570 | -637580 | 63 | 75 | ------ | |||||||

| 65 | -658040 | -658050 | -658060 | -658070 | -658080 | 65 | 80 | -6508 | |||||

| 70 | -708540 | -708550 | -708560 | -708570 | -708580 | -7085100 | 70 | 85 | -7010 | ||||

| -709050 | -709060 | -709070 | -709080 | 70 | 90 | " | |||||||

| 75 | -759050 | -759060 | -759070 | -759080 | -7090100 | 75 | 90 | -7510 | |||||

| -759560 | -759570 | -759580 | -7595100 | 75 | 95 | " | |||||||

| 80 | -809640 | -809650 | -809660 | -809670 | -809680 | -8096100 | -8096120 | 80 | 96 | -8010 | |||

| -8010040 | -8010050 | -8010060 | -8010070 | -8010080 | -80100100 | -80100120 | -80100140 | 80 | 100 | " | |||

| 90 | -9011050 | -9011060 | -9011080 | -90110100 | -90110120 | 90 | 110 | -9010 | |||||

| 100 | -10012050 | -10012060 | -10012070 | -10012080 | -100120100 | -100120120 | -100120140 | 100 | 120 | -10010 | |||

| 110 | -11013050 | -11013070 | -11013080 | -110130100 | -110130120 | 110 | 130 | ------ | |||||

| 120 | -12014070 | -12014080 | -120140100 | -120140120 | -120140140 | 120 | 140 | -12010 | |||||

| 125 | -125140100 | -125145120 | 125 | 145 | ------ | ||||||||

| 130 | -13015080 | -130150100 | -130150130 | 130 | 150 | ------ | |||||||

| 140 | -140160100 | -140160140 | 140 | 160 | ------ | ||||||||

| 150 | -15017080 | -150170100 | -150170150 | 150 | 170 | ------ | |||||||

| 160 | -16018080 | -160180100 | -160180150 | 160 | 180 | ------ | |||||||

Self-lubricated Brass Alloy Bushings #500SP (SPB) can be used in rotation, swing and reciprocating motion.

If it is subjected to axial load, please use it in combination with #500SP washer (SPW).

Please avoid using in water.

The inner diameter of 31.5mm is in the middle of the hydraulic cylinder trunnion bushing.

- Download

Self-lubricated Brass Alloy Bushings SPB | Global Supplier of Bearing Sleeves, Locking Systems & Custom Machined Parts

Chin Sing offers a full range of Self-lubricated Brass Alloy Bushings SPB, adapter sleeves, withdrawal sleeves, and hydraulic sleeves engineered for reliable bearing mounting and dismounting on cylindrical shafts. Our components are precision-machined to meet international standards like ISO 2982-1 and DIN 5415, ensuring secure fitment, extended service life, and easy maintenance in high-load applications.

These shaft sleeves are widely used in steel mills, mining conveyors, wind turbines, and other industrial machinery where downtime must be minimized. Our hydraulic options further simplify installation and removal, reducing labor time and preventing damage to bearings or shafts. Available in both metric and inch series, we cater to global OEMs and MRO buyers.

Whether you're replacing existing parts or sourcing for new builds, Chin Sing delivers high-quality solutions backed by Taiwan-based manufacturing expertise, OEM/ODM customization, and ISO-certified quality assurance. Our bearing mounting components are trusted worldwide for performance, safety, and efficiency.