Lock Washer & Plate & OEM / ODM & Hook Wrench

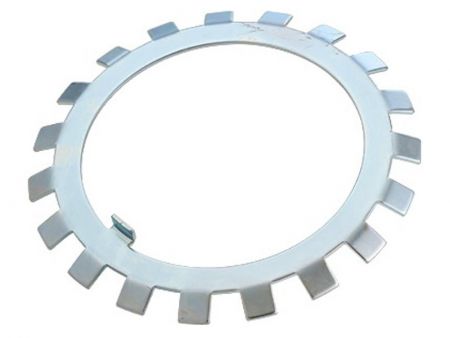

CS locking washers are made of SPCC/SPHC metal materials. Surface treatment: Zinc plated 5um, Cr3+. The purpose in using them is to keep nuts and bolts away from vibrating or friction loose. There are many different shapes and sizes, but they all try to achieve the same goal. When properly applied, lock washer provides an easy, basic way to keep threaded fasteners steady over a long period of time.

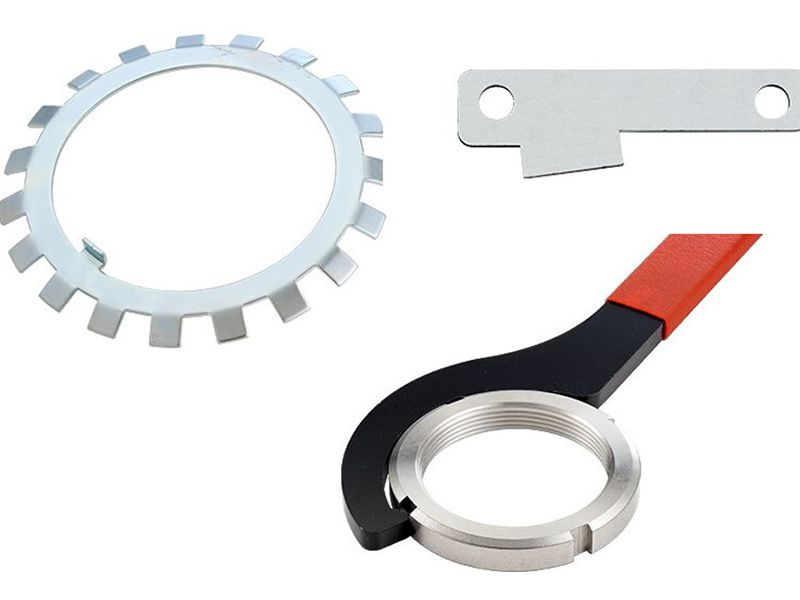

Lock Plates

Professional and experienced manufacturer of Metric lock plates with CS Brand, Metric lock plates units purpose to let lager Lock nuts from nuts 44 up to 100 be fixed.

Our lock plates are produced by Wire Electrical Discharge Machine (Wire EDM). With Wire EDM, we can produce the most complex precision components at a relatively low cost and fast production rate while maintaining high accuracy and repeatability. It assists in bearing lock nuts and suitable for large sizes to prevent dropping.

Hook Wrench Spanner

Hook wrench function is assembling the lock nuts from sleeves. Hook wrenches are used to tighten, loosen, or hold machinery components that are round but also notched or multi-faceted, such as lock nuts and pipe fittings.

Whether a hook wrench's head or the hook, is fixed in place or adjustable, the inner side of its curve usually ends in a small, downward-pointing tooth or claw. As the wrench is turned, the tooth prevents the head from slipping out of place, allowing the user to adjust the part quickly and efficiently. Due to the fact that it is available in a range of different sizes that can be used to adjust parts under varying circumferences.

In order to achieve 100% customer satisfaction and maintain a high level of quality control, our company had invested a considerable amount of capital into the precise manufacturing facilities. In addition, from raw material cutting to product production, all procedures of manufacturing have been supervised restrictively and being done in our company. For the past 31 years, we have strong suppliers and powerful customers to support our business. Our company policy is "Customer satisfaction is always our first priority", punctual delivery and excellent quality are what we pay attention to the most.

Our fast, flexible industrial production lines are organized and managed according to CNC criteria. The daily machine load are optimized by means of dedicated production scheduling, planning, and monitoring software programs, real-time information, such as coordinate measuring machine, deflection tester, surface-roughness measurement, and height gauge. Control of the production proceeding process makes it possible to precisely map the out coming quantities from each machining center. The final assembly, technical testing, and packing phases enable us to deliver our customers an excellent product with impeccable, punctual, top quality service.

Lock Washer

AW00-AW56, MB00-MB56, AWL24-AWL40, MBL24-MBL40 CS locking washers are made of SPCC / SPHC metal...

Inch Lock Washers

CS locking washers are made of SPCC / SPHC metal materials. Surface treatment: Zinc plated...

Lock Plate

Professional and experienced manufacturer of Metric lock plates with CS Brand, Metric lock...

Inch Lock Plates

Professional and well-experienced manufacturer of Inch lock plates with "CS" Brand, We are the finest...

Hook Wrench

Hook wrench function is assembling the lock nuts from sleeves. Hook wrenches are used to tighten,...

OEM / ODM

Over 30 years of experiences in professional producing adaptor sleeves, withdrawal sleeves,...

Lock Washers, Plates & Hook Wrenches – OEM & ODM

Chin Sing provides a full range of lock washers, lock plates, and hook wrenches, supporting secure assembly of bearing nuts across industrial machinery. These components are engineered to resist loosening caused by vibration and torque.

Our OEM/ODM capabilities allow for tailored sizing, material finishes, and multi-function designs that meet unique client specifications. Common in gear assemblies, shafts, and mechanical fasteners.

Choose Chin Sing for one-stop sourcing of high-performance locking accessories with dependable global shipping and flexible customization options.