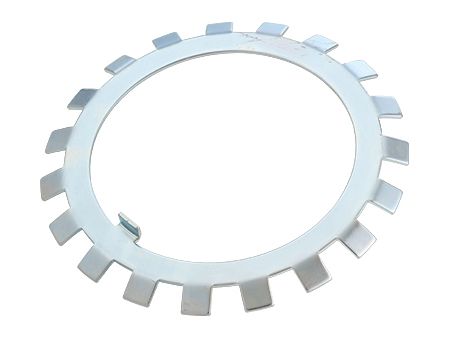

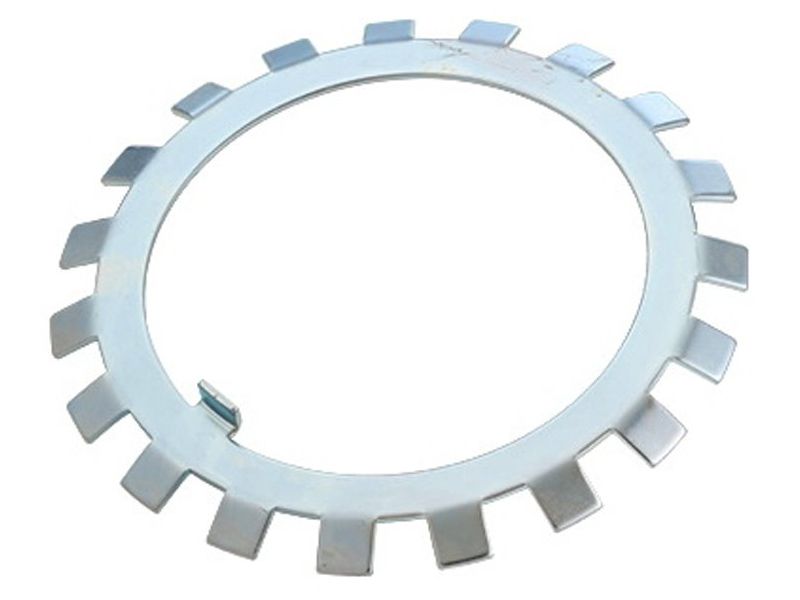

Lock Washer

AW00-AW56, MB00-MB56, AWL24-AWL40, MBL24-MBL40

CS locking washers are made of SPCC / SPHC metal materials. Surface treatment: Zinc plated 5um, Cr3+. The purpose in using them is to keep nuts and bolts away from vibrating or friction loose. There are many different shapes and sizes, but they all try to achieve the same goal. When properly applied, lock washer provides an easy, basic way to keep threaded fasteners steady over a long period of time.

MB Lock Washers

MB00-MB56 Lock washers are made of SPCC / SPHC metal materials. Surface treatment: Zinc plated...

DetailsMBL Lock Washers

MBL24-MBL40 Lock washers are made of SPCC / SPHC metal materials. Surface treatment: Zinc plated...

DetailsAW Lock Washers

AW Lock washers are made of SPCC / SPHC metal materials. Surface treatment: Zinc plated 5um,...

DetailsAWL Lock Washers

AWL Lock Washers are made of SPCC / SPHC metal materials. Surface treatment: Zinc plated 5um,...

DetailsIndustrial Lock Washers to Prevent Bearing Loosening

Chin Sing’s lock washers are designed to prevent rotation or loosening of bearing lock nuts under axial vibration or torque conditions. They are ideal for shaft-mounted assemblies and precision machinery.

Used across mining equipment, hydraulic systems, and factory automation lines, our lock washers maintain consistent locking force over repeated cycles. Available in multiple sizes, profiles, and materials.

Manufactured to ISO standards and subject to strict quality control, these washers provide trusted fastening in demanding environments.