MB Lock Washers

MB00-MB56 Lock washers are made of SPCC / SPHC metal materials. Surface treatment: Zinc plated 5um, Cr3+. The purpose in using them is to keep nuts and bolts away from vibrating or friction loose. There are many different shapes and sizes, but they all try to achieve the same goal. When properly applied, lock washer provides an easy, basic way to keep threaded fasteners steady over a long period of time.

Chin Sing Precision Industry Co., Ltd. is a professional and well-experienced manufacturer of metric lock washer with "CS" Brand, excellent quality metric lock washer manufacturer and a famous metric lock washer exporter, supplying metric lock washers to all over the world. Metric lock washer agent, metric lock washer distributor are wanted.

Model

MB00, MB01, MB02, MB03, MB04, MB05, MB06, MB07, MB08, MB09, MB10, MB11, MB12, MB13, MB14, MB15, MB16, MB17, MB18, MB19, MB20, MB21, MB22, MB23, MB24, MB25, MB26, MB27, MB28, MB29, MB30, MB31, MB32, MB33, MB34, MB36, MB38, MB40, MB44, MB48, MB52, MB56

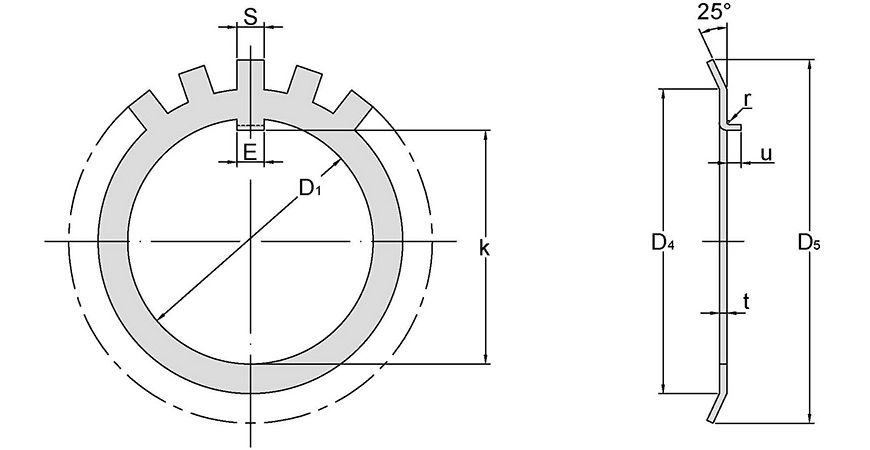

Drawing

Lock Washers - MB

Flat / Bent Tab Available

| Lock Washers No. | D1 mm | k mm | E mm | t mm | S mm | D4 mm | D5 mm | r mm | u mm | Number of Tongues | Weight per 100pcs kg | Lock Nut No. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MB00 | 10 | 8.5 | 3 | 1 | 3 | 13.5 | 21 | 0.5 | 2 | 9 | 0.131 | KM00 |

| MB01 | 12 | 10.5 | 3 | 1 | 3 | 17 | 25 | 0.5 | 2 | 9 | 0.192 | KM01 |

| MB02 | 15 | 13.5 | 4 | 1 | 4 | 21 | 28 | 1 | 2.5 | 13 | 0.253 | KM02 |

| MB03 | 17 | 15.5 | 4 | 1 | 4 | 24 | 32 | 1 | 2.5 | 13 | 0.313 | KM03 |

| MB04 | 20 | 18.5 | 4 | 1 | 4 | 26 | 36 | 1 | 2.5 | 13 | 0.350 | KM04 |

| MB05 | 25 | 23.0 | 5 | 1.2 | 5 | 32 | 42 | 1 | 2.5 | 13 | 0.640 | KM05 |

| MB06 | 30 | 27.5 | 5 | 1.2 | 5 | 38 | 49 | 1 | 2.5 | 13 | 0.780 | KM06 |

| MB07 | 35 | 32.5 | 6 | 1.2 | 5 | 44 | 57 | 1 | 2.5 | 15 | 1.040 | KM07 |

| MB08 | 40 | 37.5 | 6 | 1.2 | 6 | 50 | 62 | 1 | 2.5 | 15 | 1.230 | KM08 |

| MB09 | 45 | 42.5 | 6 | 1.2 | 6 | 56 | 69 | 1 | 2.5 | 17 | 1.520 | KM09 |

| MB10 | 50 | 47.5 | 6 | 1.2 | 6 | 61 | 74 | 1 | 2.5 | 17 | 1.600 | KM10 |

| MB11 | 55 | 52.5 | 8 | 1.5 | 7 | 67 | 81 | 1 | 4 | 17 | 1.960 | KM11 |

| MB12 | 60 | 57.5 | 8 | 1.5 | 7 | 73 | 86 | 1.2 | 4 | 17 | 2.530 | KM12 |

| MB13 | 65 | 62.5 | 8 | 1.5 | 7 | 79 | 92 | 1.2 | 4 | 19 | 2.900 | KM13 |

| MB14 | 70 | 66.5 | 8 | 1.5 | 8 | 85 | 98 | 1.2 | 4 | 19 | 3.340 | KM14 |

| MB15 | 75 | 71.5 | 8 | 1.5 | 8 | 90 | 104 | 1.2 | 4 | 19 | 3.560 | KM15 |

| MB16 | 80 | 76.5 | 10 | 1.8 | 8 | 95 | 112 | 1.2 | 4 | 19 | 4.640 | KM16 |

| MB17 | 85 | 81.5 | 10 | 1.8 | 8 | 102 | 119 | 1.2 | 4 | 19 | 5.240 | KM17 |

| MB18 | 90 | 86.5 | 10 | 1.8 | 10 | 108 | 126 | 1.2 | 4 | 19 | 6.230 | KM18 |

| MB19 | 95 | 91.5 | 10 | 1.8 | 10 | 113 | 133 | 1.2 | 4 | 19 | 6.700 | KM19 |

| MB20 | 100 | 96.5 | 12 | 1.8 | 10 | 120 | 142 | 1.2 | 6 | 19 | 7.650 | KM20 |

| MB21 | 105 | 100.5 | 12 | 1.8 | 12 | 126 | 145 | 1.2 | 6 | 19 | 8.260 | KM21 |

| MB22 | 110 | 105.5 | 12 | 1.8 | 12 | 133 | 154 | 1.2 | 6 | 19 | 9.400 | KM22 |

| MB23 | 115 | 110.5 | 12 | 2 | 12 | 137 | 159 | 1.5 | 6 | 19 | 10.800 | KM23 |

| MB24 | 120 | 115.0 | 14 | 2 | 12 | 138 | 164 | 1.5 | 6 | 19 | 10.500 | KM24 |

| MB25 | 125 | 120.0 | 14 | 2 | 12 | 148 | 170 | 1.5 | 6 | 19 | 11.800 | KM25 |

| MB26 | 130 | 125.0 | 14 | 2 | 12 | 149 | 175 | 1.5 | 6 | 19 | 11.300 | KM26 |

| MB27 | 135 | 130.0 | 14 | 2 | 14 | 160 | 185 | 1.5 | 6 | 19 | 14.400 | KM27 |

| MB28 | 140 | 135.0 | 16 | 2 | 14 | 160 | 192 | 1.5 | 8 | 19 | 14.200 | KM28 |

| MB29 | 145 | 140.0 | 16 | 2 | 14 | 171 | 202 | 1.5 | 8 | 19 | 16.800 | KM29 |

| MB30 | 150 | 145.0 | 16 | 2 | 14 | 171 | 205 | 1.5 | 8 | 19 | 15.500 | KM30 |

| MB31 | 155 | 147.5 | 16 | 2.5 | 16 | 182 | 212 | 1.5 | 8 | 19 | 20.900 | KM31 |

| MB32 | 160 | 154.0 | 18 | 2.5 | 16 | 182 | 217 | 1.5 | 8 | 19 | 22.200 | KM32 |

| MB33 | 165 | 157.5 | 18 | 2.5 | 16 | 193 | 222 | 1.5 | 8 | 19 | 24.100 | KM33 |

| MB34 | 170 | 164.0 | 18 | 2.5 | 16 | 193 | 232 | 1.5 | 8 | 19 | 24.700 | KM34 |

| MB36 | 180 | 174.0 | 20 | 2.5 | 18 | 203 | 242 | 1.5 | 8 | 19 | 26.800 | KM36 |

| MB38 | 190 | 184.0 | 20 | 2.5 | 18 | 214 | 252 | 1.5 | 8 | 19 | 27.800 | KM38 |

| MB40 | 200 | 194.0 | 20 | 2.5 | 18 | 226 | 262 | 1.5 | 8 | 19 | 29.300 | KM40 |

| MB44 | 220 | 213.0 | 24 | 3 | 20 | 250 | 292 | - | 10 | 19 | 48.300 | KM44 |

| MB48 | 240 | 233.0 | 24 | 3 | 20 | 270 | 312 | - | - | 19 | 50.200 | KM48 |

| MB52 | 260 | 253.0 | 28 | 3 | 24 | 300 | 342 | - | - | 23 | 72.900 | KM52 |

| MB56 | 280 | 273.0 | 28 | 3 | 24 | 320 | 362 | - | - | 23 | 75.900 | KM56 |

NO. MB00-MB40 also available for 304 stainless steel.

NOTE: The specifications of MB can be applied for AW.

- Download

Spec. of MB

Spec. of MB00, MB01, MB02, MB03, MB04, MB05, MB06, MB07, MB08, MB09, MB10, MB11, MB12, MB13, MB14, MB15, MB16, MB17, MB18, MB19, MB20, MB21, MB22, MB23,...

Download

MB Lock Washers | Global Supplier of Bearing Sleeves, Locking Systems & Custom Machined Parts

Chin Sing offers a full range of MB Lock Washers, adapter sleeves, withdrawal sleeves, and hydraulic sleeves engineered for reliable bearing mounting and dismounting on cylindrical shafts. Our components are precision-machined to meet international standards like ISO 2982-1 and DIN 5415, ensuring secure fitment, extended service life, and easy maintenance in high-load applications.

These shaft sleeves are widely used in steel mills, mining conveyors, wind turbines, and other industrial machinery where downtime must be minimized. Our hydraulic options further simplify installation and removal, reducing labor time and preventing damage to bearings or shafts. Available in both metric and inch series, we cater to global OEMs and MRO buyers.

Whether you're replacing existing parts or sourcing for new builds, Chin Sing delivers high-quality solutions backed by Taiwan-based manufacturing expertise, OEM/ODM customization, and ISO-certified quality assurance. Our bearing mounting components are trusted worldwide for performance, safety, and efficiency.