GUK Self-Locking Nut

GUK Self-locking nuts are self-locking due to their nylon PA6 insert. Therefore, they can also be used as retaining nuts and can be used multiple times. The thread series mainly corresponds to cylindrical bearing slotted lock nuts according to DIN 981.

GUK self-locking nuts add a nylon insert that sits on top of the nut to deform on the mating thread and catch the bolt or stud. This provides a locking function that creates resistance - or primary torque - to lock the nut in place and resist vibration.

In addition to the nylon PA6 self-locking feature, GUK self-locking nuts are equipped with four equally spaced grooves on the outside diameter of the nut, which allow a hook wrench to easily tighten or loosen the nut. These self-locking nuts are not suitable for high temperature over 100 degree applications. For further information, please contact us immediately.

• Material: Nut-SS400 Elastic Ring: PA6

• SUITABLE MAX TEMPERATURE: 100 degree.

• Finish: Zinc plated / C. TOLERANCE 4H

Model

GUK00, GUK01, GUK02, GUK03, GUK04, GUK05, GUK06, GUK07, GUK08, GUK09, GUK10, GUK11, GUK12, GUK13, GUK14, GUK15, GUK16, GUK17, GUK18, GUK19, GUK20

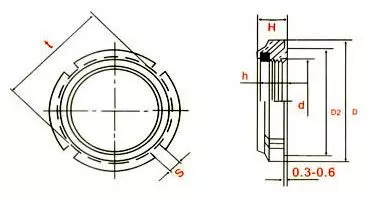

Drawing

Self-Locking Nuts - GUK

| Item NO. | Thread * pitch | H mm | h mm | D mm | D2 mm | t mm | S mm | No. of Grooves for Hook | KG |

|---|---|---|---|---|---|---|---|---|---|

| GUK00 | M10*0.75 | 7.4 | 4.5 | 18 | 15 | 15 | 3 | 4 | 0.009 |

| GUK01 | M12*1.0 | 7.4 | 4.5 | 21 | 18 | 18 | 3 | 4 | 0.009 |

| GUK02 | M15*1.0 | 8.4 | 5.5 | 24 | 21 | 21 | 4 | 4 | 0.012 |

| GUK03 | M17*1.0 | 8.4 | 5.5 | 28 | 24 | 24 | 4 | 4 | 0.018 |

| GUK04 | M20*1.0 | 9.4 | 6.5 | 32 | 27 | 27 | 4 | 4 | 0.025 |

| GUK05 | M25*1.5 | 10.3 | 6.5 | 38 | 33 | 33 | 5 | 4 | 0.035 |

| GUK06 | M30*1.5 | 10.9 | 6.5 | 44 | 38 | 38 | 5 | 4 | 0.046 |

| GUK07 | M35*1.5 | 11.1 | 7 | 50 | 44 | 44 | 5 | 4 | 0.062 |

| GUK08 | M40*1.5 | 12.1 | 8.2 | 56 | 50 | 50 | 6 | 4 | 0.080 |

| GUK09 | M45*1.5 | 12.1 | 8.2 | 62 | 55 | 55 | 6 | 4 | 0.095 |

| GUK10 | M50*1.5 | 12.7 | 8.5 | 68 | 61 | 61 | 6 | 4 | 0.130 |

| GUK11 | M55*2.0 | 13.2 | 8.5 | 75 | 68 | 68 | 7 | 6 | 0.160 |

| GUK12 | M60*2.0 | 13.2 | 8.5 | 80 | 73 | 73 | 7 | 6 | 0.170 |

| GUK13 | M65*2.0 | 14.3 | 9.5 | 85 | 77 | 77 | 7 | 6 | 0.185 |

| GUK14 | M70*2.0 | 14.3 | 9.5 | 92 | 84 | 84 | 8 | 6 | 0.230 |

| GUK15 | M75*2.0 | 15.3 | 10.5 | 98 | 89 | 89 | 8 | 6 | 0.270 |

| GUK16 | M80*2.0 | 16.3 | 11.5 | 105 | 96 | 96 | 8 | 8 | 0.340 |

| GUK17 | M85*2.0 | 17.3 | 12.5 | 110 | 100 | 100 | 8 | 8 | 0.390 |

| GUK18 | M90*2.0 | 17.5 | 12.5 | 120 | 110 | 110 | 10 | 8 | 0.540 |

| GUK19 | M95*2.0 | 18.5 | 13.5 | 125 | 115 | 115 | 10 | 8 | 0.600 |

| GUK20 | M100*2.0 | 19.5 | 14.5 | 130 | 120 | 120 | 10 | 8 | 0.680 |

* Unnecessary to add any tooth lock washer.

* Unnecessary to mill a keyway on the shaft and shorten its assembled time.

* Allow to be used after repeatedly screwing.

* Bearing any vibration and ensuring the integrated resistance when not tightened.

* The surface is galvanized to prevent rust.

- Download

Spec. of GUK

Spec. of GUK00, GUK01, GUK02, GUK03, GUK04, GUK05, GUK06, GUK07, GUK08, GUK09, GUK10, GUK11, GUK12, GUK13, GUK14, GUK15, GUK16, GUK17, GUK18, GUK19, GUK20

Download

GUK Self-Locking Nut | Global Supplier of Bearing Sleeves, Locking Systems & Custom Machined Parts

Chin Sing offers a full range of GUK Self-Locking Nut, adapter sleeves, withdrawal sleeves, and hydraulic sleeves engineered for reliable bearing mounting and dismounting on cylindrical shafts. Our components are precision-machined to meet international standards like ISO 2982-1 and DIN 5415, ensuring secure fitment, extended service life, and easy maintenance in high-load applications.

These shaft sleeves are widely used in steel mills, mining conveyors, wind turbines, and other industrial machinery where downtime must be minimized. Our hydraulic options further simplify installation and removal, reducing labor time and preventing damage to bearings or shafts. Available in both metric and inch series, we cater to global OEMs and MRO buyers.

Whether you're replacing existing parts or sourcing for new builds, Chin Sing delivers high-quality solutions backed by Taiwan-based manufacturing expertise, OEM/ODM customization, and ISO-certified quality assurance. Our bearing mounting components are trusted worldwide for performance, safety, and efficiency.