S-3000 Inch Adapter Sleeves

SNW/SNP US Size Adapter Sleeves are with dimensions in accordance with AISI standard, with lock nuts and lock washer or lock plate. Chin Sing SNW/SNP series products include US size adapter sleeves, inch lock nuts, inch lock washer, and inch lock plate.

Chin Sing provides bearing sleeves that can reach longitude 1:12/ 2° 23° 9'4, density 7.85g/mm, hardness HRB standard, SNW/SNP series sleeves conform to American standards. If you have American production requirements, Chin Sing is able to comply with U.S. production. Please visit our product description page to learn more about our SNW/SNP series standard sleeves.

Model

S-3024, S-3026, S-3028, S-3030, S-3032, S-3034, S-3036, S-3038, S-3040, S-3044, S-3048, S-3052, S-3056, S-3060, S-3064, S-3068, S-3072, S-3076, S-3080, S-3084, S-3088, S-3092, S-3096, S-30/500, S-30/530, S-30/560, S-30/600, S-30/630, S-30/670, S-30/710, S-30/750, S-30/800, S-30/850, S-30/900, S-30/950

S-3156, S-3160, S-3164, S-3168, S-3172, S-3176, S-3180, S-3184, S-3186, S-3192, S-3196, S-31/500, S-31/530, S-31/560, S-31/600, S-31/630, S-31/670, S-31/710, S-31/750, S-31/800, S-31/850

S-3256, S-3260, S-3264, S-3268, S-3272, S-3276, S-3280, S-3284, S-3288, S-3292, S-3296, S-32/500, S-32/530, S-32/560, S-32/600, S-32/630, S-32/670, S-32/710, S-32/750

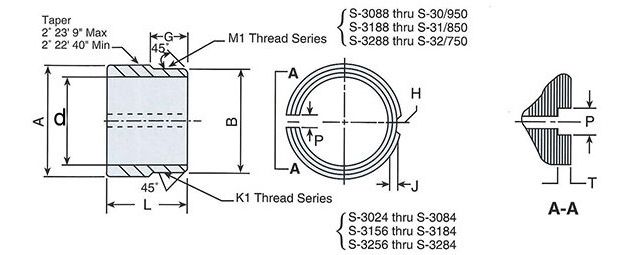

Drawing

Adapter Sleeve Dimension (Inches) - S-3000

S30| Sleeve Number | Sleeve Bore Dia | Diameter to Sharp Corner | Length | Major Diameter | Threads No. per Inch | G | Slot Width | Relief | Lockplate Slot | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d | A | L | B | F | J | H | P | T | ||||

| max | min | min | max | K1 | M1 | max | min | max | min | min | min | |

| S-3024 | 4.192 | 4.89 | 2.937 | 4.716 | 12 | 1.26 | 0.428 | |||||

| S-3026 | 4.442 | 5.304 | 3.227 | 5.106 | 12 | 1.323 | 0.552 | 0.28 | 0.13 | |||

| S-3028 | 4.942 | 5.701 | 3.33 | 5.497 | 12 | 1.385 | 0.74 | |||||

| S-3030 | 5.192 | 6.105 | 3.482 | 5.888 | 12 | 1.416 | 0.74 | 0.28 | 0.13 | |||

| S-3032 | 5.442 | 6.512 | 3.701 | 6.284 | 8 | 1.478 | 0.74 | 0.28 | 0.13 | |||

| S-3034 | 5.942 | 6.929 | 4.009 | 6.659 | 8 | 1.51 | 0.865 | |||||

| S-3036 | 6.442 | 7.346 | 4.327 | 7.066 | 8 | 1.541 | 0.865 | |||||

| S-3038 | 6.942 | 7.744 | 4.402 | 7.472 | 8 | 1.604 | 0.865 | |||||

| S-3040 | 7.192 | 8.161 | 4.74 | 7.847 | 8 | 1.666 | 0.99 | |||||

| S-3044 | 7.942 | 8.976 | 5.12 | 8.628 | 8 | 1.76 | 0.99 | |||||

| S-3048 | 8.942 | 9.771 | 5.422 | 9.442 | 6 | 1.978 | 0.302 | 1.13 | 0.5 | |||

| S-3052 | 9.444 | 10.6 | 6.009 | 10.192 | 6 | 2.135 | 0.302 | 1.19 | 0.5 | |||

| S-3056 | 10.444 | 11.394 | 6.181 | 11.004 | 6 | 2.229 | 0.302 | 1.25 | 0.5 | |||

| S-3060 | 10.944 | 12.221 | 6.717 | 11.785 | 6 | 2.291 | 0.302 | 1.38 | 0.5 | |||

| S-3064 | 11.944 | 13.02 | 6.936 | 12.562 | 6 | 2.385 | 0.302 | 1.44 | 0.5 | |||

| S-3068 | 12.444 | 13.847 | 7.533 | 13.303 | 5 | 2.541 | 0.302 | 1.5 | 0.5 | |||

| S-3072 | 13.444 | 14.639 | 7.569 | 14.134 | 5 | 2.541 | 0.365 | 1.5 | 0.5 | |||

| S-3076 | 13.944 | 15.43 | 7.733 | 14.921 | 5 | 2.666 | 0.365 | 1.5 | 0.5 | |||

| S-3080 | 15.006 | 16.26 | 8.401 | 15.709 | 5 | 2.823 | 0.365 | 1.63 | 0.5 | |||

| S-3084 | 15.756 | 17.056 | 8.488 | 16.496 | 5 | 2.823 | 0.365 | 1.63 | 0.5 | |||

| S-3088 | 16.506 | 17.868 | 9.1 | 17.283 | 5 | 3.228 | 0.365 | 1.81 | 0.5 | |||

| S-3092 | 17.006 | 18.675 | 9.336 | 18.071 | 5 | 3.228 | 0.365 | 1.81 | 0.5 | |||

| S-3096 | 18.006 | 19.469 | 9.446 | 18.858 | 5 | 3.26 | 0.365 | 1.81 | 0.5 | |||

| S-30/500 | 18.506 | 20.263 | 9.838 | 19.646 | 5 | 3.573 | 0.365 | 1.81 | 0.5 | |||

| S-30/530 | 19.506 | 21.507 | 10.579 | 20.827 | 4 | 3.573 | 0.49 | 1.81 | 0.5 | |||

| S-30/560 | 21.006 | 22.721 | 11.222 | 22.008 | 4 | 3.823 | 0.49 | 1.81 | 0.5 | |||

| S-30/600 | 22.006 | 24.316 | 11.451 | 23.583 | 4 | 3.916 | 0.49 | 1.81 | 0.5 | |||

| S-30/630 | 24.006 | 25.537 | 11.924 | 24.764 | 4 | 3.916 | 0.49 | 2 | 0.5 | |||

| S-30/670 | 25.006 | 27.175 | 12.835 | 26.339 | 4 | 4.104 | 0.49 | 2 | 0.625 | |||

| S-30/710 | 26.506 | 28.769 | 13.509 | 27.914 | 3 | 4.541 | 0.49 | 2 | 0.625 | |||

| S-30/750 | 28.006 | 30.394 | 14.093 | 29.489 | 3 | 4.541 | 0.49 | 2 | 0.625 | |||

| S-30/800 | 29.506 | 32.389 | 14.408 | 31.457 | 3 | 4.541 | 0.49 | 2 | 0.625 | |||

| S-30/850 | 31.506 | 34.407 | 14.991 | 33.426 | 3 | 4.573 | 0.49 | 2 | 0.625 | |||

| S-30/900 | 33.506 | 36.402 | 15.681 | 35.394 | 3 | 4.948 | 0.49 | 2 | 0.625 | |||

| S-30/950 | 36.506 | 38.438 | 16.492 | 37.363 | 3 | 4.948 | 0.49 | 2 | 0.625 | |||

| Sleeve Number | Sleeve Bore Dia | Diameter to Sharp Corner | Length | Major Diameter | Threads No. per Inch | G | Slot Width | Relief | Lockplate Slot | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d | A | L | B | F | J | H | P | T | ||||

| max | min | min | max | K1 | M1 | max | min | max | min | min | min | |

| S-3156 | 10.444 | 11.526 | 7.756 | 11.004 | 6 | 2.229 | 0.302 | 1.25 | 0.5 | |||

| S-3160 | 10.944 | 12.359 | 8.37 | 11.785 | 6 | 2.291 | 0.302 | 1.38 | 0.5 | |||

| S-3164 | 11.944 | 13.201 | 9.101 | 12.562 | 6 | 2.385 | 0.302 | 1.44 | 0.5 | |||

| S-3168 | 12.444 | 14.034 | 9.777 | 13.303 | 5 | 2.541 | 0.302 | 1.5 | 0.5 | |||

| S-3172 | 13.444 | 14.829 | 9.852 | 14.134 | 5 | 2.541 | 0.365 | 1.5 | 0.5 | |||

| S-3176 | 13.944 | 15.623 | 10.056 | 14.921 | 5 | 2.666 | 0.365 | 1.5 | 0.5 | |||

| S-3180 | 15.006 | 16.43 | 10.449 | 15.709 | 5 | 2.885 | 0.365 | 1.63 | 0.5 | |||

| S-3184 | 15.756 | 17.298 | 11.402 | 16.496 | 5 | 2.948 | 0.365 | 1.63 | 0.5 | |||

| S-3188 | 16.506 | 18.094 | 11.817 | 17.283 | 5 | 3.228 | 0.365 | 1.81 | 0.5 | |||

| S-3192 | 17.006 | 18.928 | 12.368 | 18.071 | 5 | 3.323 | 0.365 | 1.81 | 0.5 | |||

| S-3196 | 18.006 | 19.741 | 12.714 | 18.858 | 5 | 3.354 | 0.365 | 1.81 | 0.5 | |||

| S-31/500 | 18.506 | 20.581 | 13.657 | 19.646 | 5 | 3.666 | 0.365 | 1.81 | 0.5 | |||

| S-31/530 | 19.506 | 21.793 | 14.004 | 20.827 | 4 | 3.666 | 0.49 | 1.81 | 0.5 | |||

| S-31/560 | 21.006 | 23 | 14.569 | 22.008 | 4 | 3.916 | 0.49 | 1.81 | 0.5 | |||

| S-31/600 | 22.006 | 24.644 | 15.388 | 23.583 | 4 | 3.916 | 0.49 | 1.81 | 0.5 | |||

| S-31/630 | 24.006 | 25.875 | 15.979 | 24.764 | 4 | 3.916 | 0.49 | 2 | 0.5 | |||

| S-31/670 | 25.006 | 27.522 | 17.008 | 26.339 | 4 | 4.104 | 0.49 | 2 | 0.625 | |||

| S-31/710 | 26.506 | 29.127 | 17.801 | 27.914 | 3 | 4.635 | 0.49 | 2 | 0.625 | |||

| S-31/750 | 28.006 | 30.771 | 18.62 | 29.489 | 3 | 4.635 | 0.49 | 2 | 0.625 | |||

| S-31/800 | 29.506 | 32.772 | 19.014 | 31.457 | 3 | 4.635 | 0.49 | 2 | 0.625 | |||

| S-31/850 | 31.506 | 34.827 | 20.03 | 33.426 | 3 | 4.76 | 0.49 | 2 | 0.625 | |||

| Sleeve Number | Sleeve Bore Dia | Diameter to Sharp Corner | Length | Major Diameter | Threads No. per Inch | Slot Width | Relief | Lockplate Slot | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| d | A | L | B | F | J | H | P | T | |||

| max | min | min | max | K1 | M1 | min | max | min | min | min | |

| S-3256 | 10.444 | 11.624 | 8.937 | 11.004 | 6 | 0.302 | 1.25 | 0.5 | |||

| S-3260 | 10.944 | 12.464 | 9.63 | 11.785 | 6 | 0.302 | 1.38 | 0.5 | |||

| S-3264 | 11.944 | 13.306 | 10.361 | 12.562 | 6 | 0.302 | 1.44 | 0.5 | |||

| S-3268 | 12.444 | 14.146 | 11.116 | 13.303 | 5 | 0.302 | 1.5 | 0.5 | |||

| S-3272 | 13.444 | 14.96 | 11.427 | 14.134 | 5 | 0.365 | 1.5 | 0.5 | |||

| S-3276 | 13.944 | 15.774 | 11.867 | 14.921 | 5 | 0.365 | 1.5 | 0.5 | |||

| S-3280 | 15.006 | 16.614 | 12.654 | 15.709 | 5 | 0.365 | 1.63 | 0.5 | |||

| S-3284 | 15.756 | 17.456 | 13.292 | 16.496 | 5 | 0.365 | 1.63 | 0.5 | |||

| S-3288 | 16.506 | 18.271 | 13.943 | 17.283 | 5 | 0.365 | 1.81 | 0.5 | |||

| S-3292 | 17.006 | 19.111 | 14.573 | 18.071 | 5 | 0.365 | 1.81 | 0.5 | |||

| S-3296 | 18.006 | 19.945 | 15.155 | 18.858 | 5 | 0.365 | 1.81 | 0.5 | |||

| S-32/500 | 18.506 | 20.817 | 16.491 | 19.646 | 5 | 0.365 | 1.81 | 0.5 | |||

| S-32/530 | 19.506 | 22.065 | 17.271 | 20.827 | 4 | 0.49 | 1.81 | 0.5 | |||

| S-32/560 | 21.006 | 23.279 | 17.915 | 22.008 | 4 | 0.49 | 1.81 | 0.5 | |||

| S-32/600 | 22.006 | 24.933 | 18.853 | 23.583 | 4 | 0.49 | 1.81 | 0.5 | |||

| S-32/630 | 24.006 | 26.193 | 19.798 | 24.764 | 4 | 0.49 | 2 | 0.5 | |||

| S-32/670 | 25.006 | 27.857 | 21.024 | 26.339 | 4 | 0.49 | 2 | 0.625 | |||

| S-32/710 | 26.506 | 29.471 | 21.935 | 27.914 | 3 | 0.49 | 2 | 0.625 | |||

| S-32/750 | 28.006 | 31.132 | 22.982 | 29.489 | 3 | 0.49 | 2 | 0.625 | |||

- Download

Spec. of S-3000

Spec. of S-3024, S-3026, S-3028, S-3030, S-3032, S-3034, S-3036, S-3038, S-3040, S-3044, S-3048, S-3052, S-3056, S-3060, S-3064, S-3068, S-3072, S-3076,...

Download

S-3000 Inch Adapter Sleeves for Industrial Mounting Systems

The S-3000 series inch adapter sleeves by Chin Sing are manufactured to deliver robust mounting solutions for bearings on imperial-sized shafts. These sleeves are engineered for high-vibration, high-torque applications where inch-standard hardware is required.

Frequently used in American-made machinery, off-road vehicles, and HVAC systems, S-3000 sleeves are compatible with matched lock nuts and washers. Their accurate fit reduces shaft stress and ensures consistent axial load transfer.

Trust Chin Sing’s S-3000 adapter sleeves for long-term performance, easy installation, and compatibility with major inch-based systems.