AOH 241 Hydraulic Withdrawal Sleeves

AOH 241 Hydraulic Withdrawal Sleeves for metric shafts, for metric spindle. The withdrawal sleeves is one of the more popular and common used industrial sleeves. It can be used to mount bearings dismount with a tapered bore on the cylindrical seat of stepped shafts. Hydraulic bearing sleeves facilitate mounting on large bearings. An oil pump is required to inject pressurized oil. There are oil passages on the threaded side and grooves on the outer surface which can be filled with internal oil according to requirements. It is convenient for installation and the disassembly of components.

Model

AOH24144, AOH24148, AOH24152, AOH24156, AOH24160, AOH24164, AOH24168, AOH24172, AOH24176, AOH24180, AOH24184, AOH24188, AOH24192, AOH24196, AOH241/500

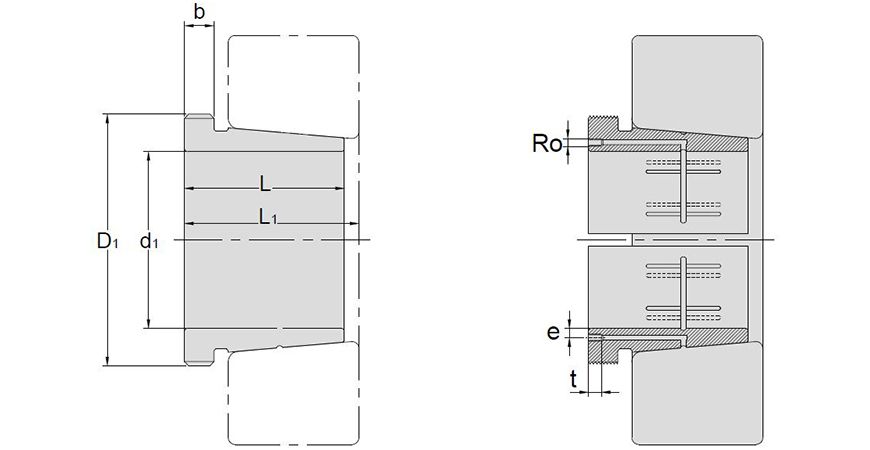

Drawing

Hydraulic Withdrawal Sleeves - AOH 241

TAPER 1:12

| Hydraulic Withdrawal Sleeves NO. | d1 | L | L | b | Ro | e | t | Thread2) | Appropriate Withdrawal Nut No. | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| D1 | ||||||||||

| mm | mm | mm | mm | mm | mm | mm | kg | |||

| AOH24144 | 200 | 170 | 184 | 20 | M6 | 8 | 8 | Tr230*4 | HN46 | 10.2 |

| AOH24148 | 220 | 180 | 195 | 20 | G1/8 | 8.5 | 12 | Tr260*4 | HN52 | 12.5 |

| AOH24152 | 240 | 202 | 218 | 22 | G1/8 | 8.5 | 12 | Tr280*4 | HN56 | 15.4 |

| AOH24156 | 260 | 202 | 219 | 22 | G1/8 | 8.5 | 12 | Tr300*4 | HN60 | 16.3 |

| AOH24160 | 280 | 224 | 242 | 24 | G1/8 | 8.5 | 12 | Tr320*5 | HN64 | 19.5 |

| AOH24164 | 300 | 242 | 260 | 24 | G1/8 | 8.5 | 12 | Tr340*5 | HN68 | 21.4 |

| AOH24168 | 320 | 269 | 288 | 26 | G1/8 | 8.5 | 12 | Tr360*5 | HN72 | 27.1 |

| AOH24172 | 340 | 269 | 289 | 26 | G1/8 | 8.5 | 12 | Tr380*5 | HN76 | 29.6 |

| AOH24176 | 360 | 271 | 291 | 28 | G1/8 | 8.5 | 12 | Tr400*5 | HN80 | 31.3 |

| AOH24180 | 380 | 278 | 298 | 28 | G1/8 | 8.5 | 12 | Tr420*5 | HN84 | 34.4 |

| AOH24184 | 400 | 310 | 332 | 30 | G1/8 | 8.5 | 12 | Tr440*5 | HN88 | 40.3 |

| AOH24188 | 420 | 310 | 332 | 30 | G1/8 | 8.5 | 12 | Tr460*5 | HN92 | 42.3 |

| AOH24192 | 440 | 332 | 355 | 32 | G1/8 | 8.5 | 12 | Tr480*5 | HN96 | 47.6 |

| AOH24196 | 460 | 343 | 368 | 35 | G1/8 | 8.5 | 12 | Tr500*5 | HN100 | 52.7 |

| AOH241/500 | 480 | 362 | 387 | 37 | G1/8 | 8.5 | 12 | Tr530*6 | HN104 | 58.8 |

⊚ Dimension L1 decreases as the Hydraulic withdrawal sleeve is driven in during mounting.

⊚ M means metric thread. Tr means 30°, trapezoid thread and the digits are outside diameter of thread and pitch.

- Download

Spec. of AOH241

Spec. of AOH24144, AOH24148, AOH24152, AOH24156, AOH24160, AOH24164, AOH24168, AOH24172, AOH24176, AOH24180, AOH24184, AOH24188, AOH24192, AOH24196, AOH241/500

Download

AOH-241 Hydraulic Withdrawal Sleeves for Extra-Large Bearings

The AOH-241 series is Chin Sing’s premium hydraulic sleeve for the largest bearing systems in industrial use. Its oil-assist design reduces friction and ensures safe dismounting in high-load conditions like wind turbines, marine propulsion, and bulk material handling.

Precision-cut grooves ensure even hydraulic force, while the sleeve’s ISO-certified geometry ensures a precise, repeatable fit every time. Ideal for OEMs and MROs needing efficiency and safety at scale.

Rely on AOH-241 sleeves to maintain equipment reliability, reduce service costs, and minimize unplanned downtime in your largest rotating machinery.