Prevailing torque bearing nut with metal inserts

Prevailing torque bearing nut with metal insert AN00-AN20 adds the special tightly-locking ring of spring SUS301 steel according to the engineering principles. When used, the ring of spring SUS301 steel was clipped and pressed into the slot. The performance of shockproof and anti-loosening are 100%, and during repeated use, it would not affect the thread of the screw and the tight-locking ring of spring SUS301 steel. Prevailing torque bearing nut with metal insert can resist during variation of temperature from -30°C to +300°C and erosion of all kinds of oil (such as gasoline, petroleum, alcohol, etc.)

The advantages of Prevailing torque bearing nut with metal insert are: no need to use a sun washer, no need to process shaft groove, reduce assembling time, ensure the nut tightly, allow to be used repeatedly, anti-vibration, surface galvanized, and anti-rust. Its characteristics remove the traditional operation method, extend the life cycle of the machine, increase work efficiency, and improve the safety of the machine. There are 3 different options of material available: SAE1008 low carbon steel, C1045 medium carbon steel and SUS304 stainless steel.

Chin Sing Prevailing torque bearing nut with metal insert is precisely manufactured by CNC machine, if you are looking for the highest quality of Prevailing torque bearing nut with metal insert, please contact us to learn more about our product information.

Model

AN00, AN01, AN02, AN03, AN04, AN05, AN06, AN07, AN08, AN09, AN10, AN11, AN12, AN13, AN14, AN15, AN16, AN17, AN18, AN19, AN20

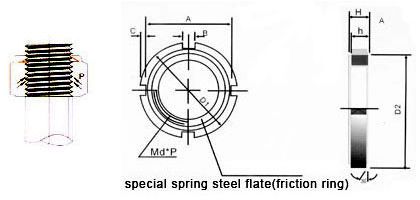

Drawing

Prevailing torque bearing nut with metal inserts

Material Option:

SAE1008 Low Carbon Steel

C1045 Medium Carbon Steel

SUS304 Stainless Steel

| Lock Nuts NO. | Thread (d x p) | D1 | D2 | A | C | B | h | H | Kg | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AN00 | M 10 x 0.75 | 18 | 0 - 0.2 | 13 | +0.2 | 14 (14.4) | 0 - 0.2 | 2 (1.8) | 3 | 0.1 | 4 | 5.2 | 0.3 | 0.0070 |

| AN01 | M 12 x 1 | 22 | 0 - 0.2 | 17 | +0.2 | 18 (18.4) | 0 - 0.2 | 2 (1.8) | 3 | 0.1 | 4 | 5.4 | 0.3 | 0.0075 |

| AN02 | M 15 x 1 | 25 | 0 - 0.5 | 21 | 0 - 0.5 | 21 (21.4) | 0 - 0.5 | 2 (1.8) | 4 | 0.2 | 5 | 6.5 | 0.5 | 0.0100 |

| AN03 | M 17 x 1 | 28 | 0 - 0.5 | 24 | 0 - 0.5 | 24 (24.2) | 0 - 0.5 | 2 (1.9) | 4 | 0.2 | 5 | 6.4 | 0.5 | 0.0140 |

| AN04 | M 20 x 1 | 32 | 0 - 0.5 | 26 | 0 - 0.5 | 28 (28.4) | 0 - 0.5 | 2 (1.8) | 4 | 0.2 | 6 | 7.7 | 0.5 | 0.0220 |

| AN05 | M 25 x 1.5 | 38 | 0 - 0.5 | 32 | 0 - 0.5 | 34 | 0 - 0.5 | 2 | 5 | 0.2 | 7 | 9.1 | 0.5 | 0.0350 |

| AN06 | M 30 x 1.5 | 45 | 0 - 0.5 | 38 | 0 - 0.5 | 41 | 0 - 0.5 | 2 | 5 | 0.2 | 7 | 9.1 | 0.8 | 0.0480 |

| AN07 | M35 x 1.5 | 52 | 0 - 0.5 | 44 | 0 - 0.5 | 48 | 0 - 0.5 | 2 | 5 | 0.2 | 8 | 10.2 | 0.8 | 0.0750 |

| AN08 | M 40 x 1.5 | 58 | 0 - 0.5 | 50 | 0 - 0.5 | 53 | 0 - 0.5 | 2.5 | 6 | 0.2 | 9 | 11.2 | 0.8 | 0.0980 |

| AN09 | M 45 x 1.5 | 65 | 0 - 0.5 | 56 | 0 - 0.5 | 60 | 0 - 0.5 | 2.5 | 6 | 0.2 | 10 | 12.5 | 1.0 | 0.1400 |

| AN10 | M 50 x 1.5 | 70 | 0 - 0.5 | 61 | 0 - 0.5 | 65 | 0 - 0.5 | 2.5 | 6 | 0.2 | 11 | 13.5 | 1.0 | 0.1670 |

| AN11 | M 55 x 2 | 75 | 0 - 0.5 | 67 | 0 - 0.5 | 69 | 0 - 0.5 | 3 | 7 | 0.2 | 11 | 13.5 | 1.0 | 0.1700 |

| AN12 | M 60 x 2 | 80 | 0 - 0.5 | 73 | 0 - 0.5 | 74 | 0 - 0.5 | 3 | 7 | 0.2 | 11 | 13.5 | 1.0 | 0.1950 |

| AN13 | M 65 x 2 | 85 | 0 - 0.5 | 79 | 0 - 0.5 | 79 | 0 - 0.5 | 3 | 7 | 0.2 | 12 | 15.0 | 1.5 | 0.2240 |

| AN14 | M 70 x 2 | 92 | 0 - 0.5 | 85 | 0 - 0.5 | 85 | 0 - 0.5 | 3.5 | 8 | 0.2 | 12 | 15.0 | 1.5 | 0.2920 |

| AN15 | M 75 x 2 | 98 | 0 - 0.5 | 90 | 0 - 0.5 | 91 | 0 - 0.5 | 3.5 | 8 | 0.2 | 13 | 15.8 | 1.5 | 0.3300 |

| AN16 | M 80 x 2 | 105 | 0 - 0.5 | 95 | 0 - 0.5 | 98 | 0 - 0.5 | 3.5 | 8 | 0.2 | 15 | 18.6 | 1.5 | 0.4200 |

| AN17 | M 85 x 2 | 110 | 0 - 0.5 | 102 | 0 - 0.75 | 103 | 0 - 0.5 | 3.5 | 8 | 0.2 | 16 | 19.2 | 1.5 | 0.5050 |

| AN18 | M 90 x 2 | 120 | 0 - 0.5 | 108 | 0 - 0.75 | 112 | 0 - 0.5 | 4 | 10 | 0.3 | 16 | 20.3 | 1.5 | 0.6900 |

| AN19 | M 95 x 2 | 125 | 0 - 0.5 | 113 | 0 - 0.75 | 117 | 0 - 0.5 | 4 | 10 | 0.3 | 17 | 21.3 | 1.5 | 0.7550 |

| AN20 | M 100 x 2 | 130 | 0 - 0.5 | 120 | 0 - 0.75 | 122 | 0 - 0.5 | 4 | 10 | 0.3 | 18 | 22.3 | 1.5 | 0.8550 |

Dismiss the traditional manufacturing method.

Prolong the life cycle of machinery.

Increase the manufacturing efficiency.

Raise the machinery safety.

- Download

Spec. of Prevailing torque bearing nut with metal inserts

Spec. of AN00, AN01, AN02, AN03, AN04, AN05, AN06, AN07, AN08, AN09, AN10, AN11, AN12, AN13, AN14, AN15, AN16, AN17, AN18, AN19, AN20

Download

Prevailing torque bearing nut with metal inserts | Global Supplier of Bearing Sleeves, Locking Systems & Custom Machined Parts

Chin Sing offers a full range of Prevailing torque bearing nut with metal inserts, adapter sleeves, withdrawal sleeves, and hydraulic sleeves engineered for reliable bearing mounting and dismounting on cylindrical shafts. Our components are precision-machined to meet international standards like ISO 2982-1 and DIN 5415, ensuring secure fitment, extended service life, and easy maintenance in high-load applications.

These shaft sleeves are widely used in steel mills, mining conveyors, wind turbines, and other industrial machinery where downtime must be minimized. Our hydraulic options further simplify installation and removal, reducing labor time and preventing damage to bearings or shafts. Available in both metric and inch series, we cater to global OEMs and MRO buyers.

Whether you're replacing existing parts or sourcing for new builds, Chin Sing delivers high-quality solutions backed by Taiwan-based manufacturing expertise, OEM/ODM customization, and ISO-certified quality assurance. Our bearing mounting components are trusted worldwide for performance, safety, and efficiency.