AH 31 Withdrawal Sleeves

AH 31 Withdrawal Sleeves can mount a tapered bore bearing on a round stepped shaft, which is one of the more popular and commonly used industrial sleeves. Generally, the withdrawal sleeve was pressed into a bearing inner bore to fix it on the shaft through a fiber web or endplate. For larger bearings, when it was pressed against the bearing bore, a larger force is required to overcome the friction of the mating surface. Hydraulic installation can simplify this process by a withdrawal sleeve.

Model

AHX3120, AHX3122, AHX3124, AHX3126, AHX3128, AHX3130, AH3132, AH3134, AH3136, AH3138, AH3140, AH3144, AH3148, AH3152, AH3156, AH3160, AH3164, AH3168, AH3172, AH3176, AH3180, AH3184, AHX3188, AHX3192, AHX3196, AHX31/500

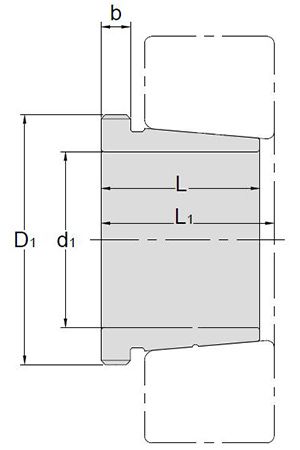

Drawing

Withdrawal Sleeves - AH 31

TAPER 1:12

| Withdrawal Sleeves NO. | d1 | L | L | b | Thread2) | Appropriate Withdrawal Nut No. | Weight |

|---|---|---|---|---|---|---|---|

| D1 | |||||||

| mm | mm | mm | mm | mm | kg | ||

| AHX3120 | 95 | 64 | 68 | 11 | M110*2 | AN22 | 0.65 |

| AHX3122 | 105 | 68 | 72 | 11 | M120*2 | AN24 | 0.76 |

| AHX3124 | 115 | 75 | 79 | 12 | M130*2 | AN26 | 0.95 |

| AHX3126 | 125 | 78 | 82 | 12 | M140*2 | AN28 | 1.08 |

| AHX3128 | 135 | 83 | 88 | 14 | M150*2 | AN30 | 1.28 |

| AHX3130 | 145 | 96 | 101 | 15 | M165*3 | AN33 | 1.79 |

| AH3132 | 150 | 103 | 108 | 16 | M180*3 | AN36 | 3.21 |

| AH3134 | 160 | 104 | 109 | 16 | M190*3 | AN38 | 3.4 |

| AH3136 | 170 | 116 | 122 | 19 | M200*3 | AN40 | 4.22 |

| AH3138 | 180 | 125 | 131 | 20 | Tr210*4 | HN42 | 4.89 |

| AH3140 | 190 | 134 | 140 | 21 | Tr220*4 | HN44 | 5.49 |

| AH3144 | 200 | 145 | 151 | 23 | Tr240*4 | HN48 | 10.4 |

| AH3148 | 220 | 154 | 161 | 25 | Tr260*4 | HN52 | 12 |

| AH3152 | 240 | 172 | 179 | 26 | Tr290*4 | HN58 | 16.2 |

| AH3156 | 260 | 175 | 183 | 28 | Tr310*5 | HN62 | 17.5 |

| AH3160 | 280 | 192 | 200 | 30 | Tr330*5 | HN66 | 20.8 |

| AH3164 | 300 | 209 | 217 | 31 | Tr350*5 | HN70 | 24.5 |

| AH3168 | 320 | 225 | 234 | 33 | Tr370*5 | HN74 | 29 |

| AH3172 | 340 | 229 | 238 | 35 | Tr400*5 | HN80 | 33 |

| AH3176 | 360 | 232 | 242 | 36 | Tr420*5 | HN84 | 35.7 |

| AH3180 | 380 | 240 | 250 | 38 | Tr440*5 | HN88 | 39.5 |

| AH3184 | 400 | 266 | 276 | 40 | Tr460*5 | HN92 | 46.5 |

| AHX3188 | 420 | 270 | 281 | 42 | Tr480*5 | HN96 | 49.8 |

| AHX3192 | 440 | 285 | 296 | 43 | Tr510*6 | HN102 | 57.9 |

| AHX3196 | 460 | 295 | 307 | 45 | Tr530*6 | HN106 | 63.1 |

| AHX31/500 | 480 | 313 | 325 | 47 | Tr550*6 | HN110 | 70.9 |

⊚ Dimension L1 decreases as the withdrawal sleeve is driven in during mounting.

⊚ M means metric thread. Tr means 30°, trapezoid thread and the digits are outside diameter of thread and pitch.

- Download

Spec. of AH31

Spec. of AHX3120, AHX3122, AHX3124, AHX3126, AHX3128, AHX3130, AH3132, AH3134, AH3136, AH3138, AH3140, AH3144, AH3148, AH3152, AH3156, AH3160, AH3164,...

Download

AH31 Withdrawal Sleeves for High-Precision Bearing Systems

Chin Sing’s AH31 withdrawal sleeves provide a reliable interface for dismounting large tapered bore bearings. The sleeves help maintain shaft integrity while enabling smooth, damage-free bearing removal in industrial environments.

Commonly used in turbines, bulk handling equipment, and automated machinery, these sleeves offer a safe and efficient solution for scheduled maintenance and rebuilds.

Crafted with high-quality alloy steel and ISO-compliant geometry, AH31 sleeves deliver long-lasting accuracy and support in critical bearing disassembly tasks.