Ball Screw FSI

FSI Ball screw is a mechanical device consisting of a screw shaft and a nut which contain steel ball that rolls between their matching helical grooves. The primary function of ball screws is to convert rotational motion to linear motion. The use of nut provides high efficiency, high load capacity, and positioning accuracy.

Material

High Carbon Steel with medium frequency induction treatment

Hardness: HRC58-62

Variation per 300mm (e300) (JIS B 1192)

| Grade | C0 | C1 | C2 | C3 | C5 | C7 | C10 |

|---|---|---|---|---|---|---|---|

| e300 | 0.0035 | 0.005 | 0.007 | 0.008 | 0.018 | 0.05 | 0.21 |

Selection of Nut

1. Series: When making selection of series, please take into consideration of demanded accuracy, dimensions, and preload, etc.

2. Circulation Type:

(a) External Circulation Type

● Economy ● Suitable for mass production ● Applicable to those with larger lead or larger outside diameter of screw shaft

(b) Internal Circulation Type

● With nuts of finely crafted outside diameter (occupying small space)

● Applicable to those with small lead or small outside diameter of the screw

(c) High Lead Type

● High Speed, High DN Value ● Low noise, Green product ● Small Size, Space saving

3. Number of Loop Circuits: Performance and life service should be considered when selecting number of loop circuits.

4. Shape of Flanges: Please make selection based on the available space for the installation of nuts.

5. Oil Hole: Oil holes are provided for the precision Ball Screws, it can be used during machine assembling and regular maintenance.

External Ball Circulation Nuts

* Feature:

1. Provide Smoother Ball Running

2. Provides better quality for long lead or large diameter of ball screws

Internal Ball Circulation Nuts

* Feature:

It is suitable for the machine with limit space for Ball Screw installation. And it is strictly required the screw shaft must contain min one end with complete threads. In order to assemble successfully, the rest area next to this complete thread must be with smaller diameter than the nominal diameter of the screw shaft.

High Lead Ball Screw

* Feature:

1. High DN Value

● The DN value can be 130,000 in normal case. For some special cases, for example, in a fixed ends case, the DN value can be as high as 140,000.

2. High Speed

● High speed ball screws provide 100 m/min and even higher speed for machine tools.

3. High Rigidity

● Screw shaft and nut are both surface hardened to a specific hardness and case depth to maintain high rigidity and durability.

● Multiple thread starts are available to make more steel balls loaded in the nut for higher rigidity and durability.

4. Low Noise

● Special design of ball circulation tubes which provide smooth ball circulation inside the nut. It also makes steel ball running into the tubes without damaging the tubes.

● Accurate ball circle diameter through whole threads for consistent drag torque and low noise.

Model

1404-4, 1405-3, 1604-4, 1605-3, 1605-4, 1610-3, 2005-4, 2504-4, 2505-4, 2510-4, 3205-4, 3206-4, 3210-4, 4005-4, 4010-4, 5010-4, 6310-4, 6320-3, 8010-4, 8020-3

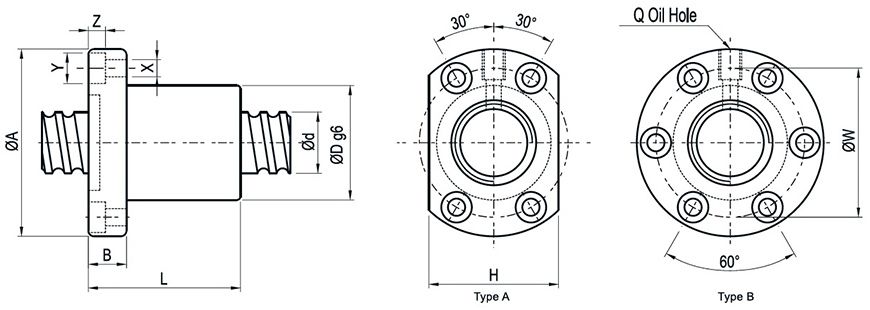

Drawing

Ball Screw (FSI)

| Model No. | Dimension | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d | I | Da | D | A | B | L | W | X | Y | Z | Type | H | Q | n | Ca (Kgf) | Coa (kgf) | |

| 1404-4 | 14 | 4 | 2.381 | 26 | 46 | 10 | 47 | 36 | 4.5 | 8 | 4.5 | A | 34 | M6 | T4 | 875 | 1056 |

| 1405-3 | 14 | 5 | 3.175 | 26 | 46 | 10 | 45 | 36 | 4.5 | 8 | 4.5 | A | 34 | M6 | T3 | 1013 | 1056 |

| 1604-4 | 16 | 4 | 2.381 | 30 | 49 | 10 | 45 | 39 | 4.5 | 8 | 4.5 | A | 34 | M6 | T4 | 944 | 1254 |

| ★1605-3 | 16 | 5 | 3.175 | 30 | 49 | 10 | 42 | 39 | 4.5 | 8 | 4.5 | A | 34 | M6 | T3 | 1049 | 1144 |

| ★1605-4 | 16 | 5 | 3.175 | 30 | 49 | 10 | 50 | 39 | 4.5 | 8 | 4.5 | A | 34 | M6 | T4 | 1344 | 1525 |

| 1610-3 | 16 | 10 | 3.175 | 34 | 58 | 10 | 65 | 45 | 5.5 | 9.5 | 5.5 | A | 36 | M6 | T3 | 1084 | 1232 |

| ★2005-4 | 20 | 5 | 3.175 | 34 | 57 | 12 | 53 | 45 | 5.5 | 9.5 | 5.5 | A | 40 | M6 | T4 | 1512 | 1995 |

| 2504-4 | 25 | 4 | 2.381 | 40 | 63 | 11 | 46 | 51 | 5.5 | 9.5 | 5.5 | A | 46 | M6 | T4 | 1178 | 2046 |

| ★2505-4 | 25 | 5 | 3.175 | 40 | 63 | 12 | 53 | 51 | 5.5 | 9.5 | 5.5 | A | 46 | M8 | T4 | 1704 | 2581 |

| 2510-4 | 25 | 10 | 4.762 | 46 | 72 | 12 | 85 | 58 | 6.5 | 11 | 6.5 | A | 52 | M6 | T4 | 2881 | 3695 |

| ★3205-4 | 32 | 5 | 3.175 | 46 | 72 | 12 | 53 | 58 | 6.5 | 11 | 6.5 | A | 52 | M8 | T4 | 1924 | 3403 |

| 3206-4 | 32 | 6 | 3.969 | 62 | 89 | 12 | 63 | 75 | 6.5 | 11 | 6.5 | B | - | M8 | T4 | 2598 | 4217 |

| 3210-4 | 32 | 10 | 6.35 | 54 | 88 | 16 | 90 | 70 | 9 | 14 | 8.5 | A | 62 | M8 | T4 | 4834 | 7835 |

| ★4005-4 | 40 | 5 | 3.175 | 56 | 90 | 16 | 56 | 72 | 9 | 14 | 8.5 | A | 64 | M8 | T4 | 2142 | 4342 |

| 4010-4 | 40 | 10 | 6.35 | 62 | 104 | 18 | 93 | 82 | 11 | 17.5 | 11 | A | 70 | M8 | T4 | 5399 | 10074 |

| 5010-4 | 50 | 10 | 6.35 | 72 | 114 | 18 | 93 | 92 | 11 | 17.5 | 11 | A | 82 | M8 | T4 | 5933 | 12313 |

| 6310-4 | 63 | 10 | 6.35 | 85 | 131 | 22 | 100 | 107 | 14 | 20 | 13 | B | - | M8 | T4 | 6700 | 16230 |

| 6320-3 | 63 | 20 | 9.525 | 95 | 153 | 23 | 130 | 123 | 18 | 26 | 17.5 | B | - | M8 | T3 | 8957 | 17945 |

| 8010-4 | 80 | 10 | 6.35 | 105 | 150 | 22 | 92 | 127 | 14 | 20 | 13 | B | - | M8 | T4 | 7547 | 21268 |

| 8020-3 | 80 | 20 | 9.525 | 115 | 173 | 23 | 130 | 143 | 18 | 26 | 17.5 | B | - | M8 | T3 | 10168 | 23611 |

★ Can be produced left-hand thread.

- Download

Spec. of Ball Screw FSI

Spec. of 1404-4, 1405-3, 1604-4, 1605-3, 1605-4, 1610-3, 2005-4, 2504-4, 2505-4, 2510-4, 3205-4, 3206-4, 3210-4, 4005-4, 4010-4, 5010-4, 6310-4, 6320-3,...

Download

Ball Screw FSI | Global Supplier of Bearing Sleeves, Locking Systems & Custom Machined Parts

Chin Sing offers a full range of Ball Screw FSI, adapter sleeves, withdrawal sleeves, and hydraulic sleeves engineered for reliable bearing mounting and dismounting on cylindrical shafts. Our components are precision-machined to meet international standards like ISO 2982-1 and DIN 5415, ensuring secure fitment, extended service life, and easy maintenance in high-load applications.

These shaft sleeves are widely used in steel mills, mining conveyors, wind turbines, and other industrial machinery where downtime must be minimized. Our hydraulic options further simplify installation and removal, reducing labor time and preventing damage to bearings or shafts. Available in both metric and inch series, we cater to global OEMs and MRO buyers.

Whether you're replacing existing parts or sourcing for new builds, Chin Sing delivers high-quality solutions backed by Taiwan-based manufacturing expertise, OEM/ODM customization, and ISO-certified quality assurance. Our bearing mounting components are trusted worldwide for performance, safety, and efficiency.