HOH 39 Hydraulic Adapter Sleeves

HOH 3936-HOH39/500 Hydraulic adapter sleeves facilitate mounting on large bearings. An oil pump is required to inject pressurized oil. There are oil passages on the threaded side and grooves on the outer surface which can be filled with internal oil according to requirements. It is convenient for installation and the disassembly of components.

The hydraulic sleeve has the characteristics of prolonging the life of the bearing and protecting the bearing. It can be used in steel construction, cement mining, textile industry, etc. We use high-quality materials to ensure and improve the quality and life cycle of hydraulic bearing sleeves.

Model

HOH3936, HOH3938, HOH3940, HOH3944, HOH3948, HOH3952, HOH3956, HOH3960, HOH3964, HOH3968, HOH3972, HOH3976, HOH3980, HOH3984, HOH3988, HOH3992, HOH3996, HOH39/500

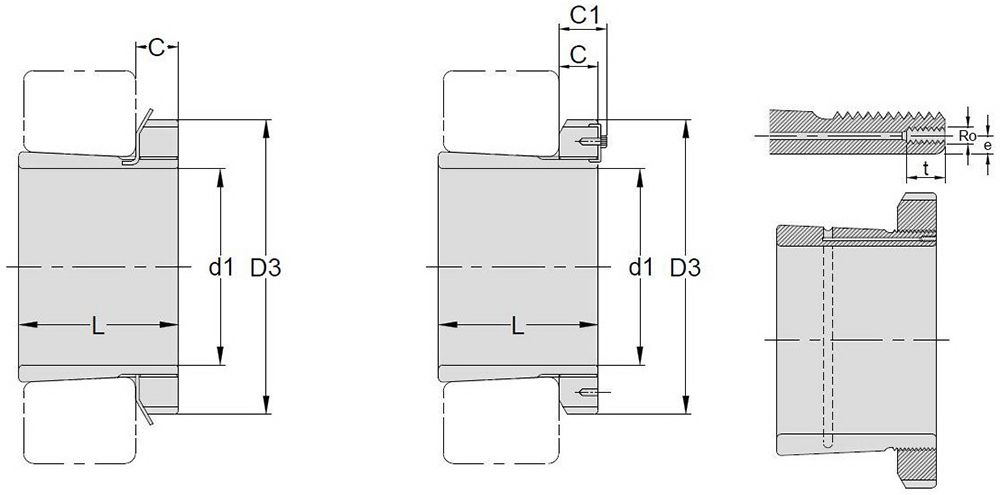

Drawing

Hydraulic Adapter Sleeves - HOH 39

TAPER 1:12

| Hydraulic Adapter Sleeve NO. | d1 | L | D3 | C | C | Ro | e | t | Lock Nut | Lock Washer & Lock Plate | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|

| H | |||||||||||

| mm | mm | mm | mm | mm | mm | mm | kg | ||||

| HOH3936 | 160 | 87 | 210 | 30 | - | M6 | 4.2 | 8 | ANL36 | AWL36 | 5.7 |

| HOH3938 | 170 | 89 | 220 | 31 | - | M6 | 4.2 | 8 | ANL38 | AWL38 | 6.19 |

| HOH3940 | 180 | 98 | 240 | 32 | - | M6 | 4.2 | 8 | ANL40 | AWL40 | 7.89 |

| HOH3944 | 200 | 96 | 260 | 30 | 41 | M6 | 4.2 | 8 | ANL44 | ALL44 | 8.16 |

| HOH3948 | 220 | 101 | 290 | 34 | 46 | M6 | 4.2 | 8 | ANL48 | ALL48 | 10.7 |

| HOH3952 | 240 | 116 | 310 | 34 | 46 | M6 | 4.2 | 8 | ANL52 | ALL52 | 12.8 |

| HOH3956 | 260 | 121 | 330 | 38 | 50 | M6 | 4.2 | 8 | ANL56 | ALL56 | 14.8 |

| HOH3960 | 280 | 140 | 360 | 42 | 54 | M6 | 4.2 | 8 | ANL60 | ALL60 | 19.8 |

| HOH3964 | 300 | 140 | 380 | 42 | 55 | M6 | 3.5 | 8 | ANL64 | ALL64 | 21 |

| HOH3968 | 320 | 144 | 400 | 45 | 58 | M6 | 3.5 | 8 | ANL68 | ALL68 | 23.5 |

| HOH3972 | 340 | 144 | 420 | 45 | 58 | M6 | 3.5 | 8 | ANL72 | ALL72 | 24.5 |

| HOH3976 | 360 | 164 | 450 | 48 | 62 | M6 | 3.5 | 8 | ANL76 | ALL76 | 31.5 |

| HOH3980 | 380 | 168 | 470 | 52 | 66 | M6 | 3.5 | 8 | ANL80 | ALL80 | 35 |

| HOH3984 | 400 | 168 | 490 | 52 | 66 | M6 | 3.5 | 8 | ANL84 | ALL84 | 36.6 |

| HOH3988 | 410 | 189 | 520 | 60 | 77 | M8 | 6.5 | 12 | ANL88 | ALL88 | 57.3 |

| HOH3992 | 430 | 189 | 540 | 60 | 77 | M8 | 6.5 | 12 | ANL92 | ALL92 | 59.9 |

| HOH3996 | 450 | 200 | 560 | 60 | 77 | M8 | 6.5 | 12 | ANL96 | ALL96 | 64.9 |

| HOH39/500 | 470 | 208 | 580 | 68 | 85 | M8 | 6.5 | 12 | ANL100 | ALL100 | 73.1 |

CS Hydraulic adapter sleeves are supplied completely with lock nuts and lock washers or lock plates.

- Download

Spec. of HOH39

Spec. of HOH3936, HOH3938, HOH3940, HOH3944, HOH3948, HOH3952, HOH3956, HOH3960, HOH3964, HOH3968, HOH3972, HOH3976, HOH3980, HOH3984, HOH3988, HOH3992,...

Download

What makes HOH 39 hydraulic sleeves the preferred choice for critical mining equipment where reliability is essential?

Mining operations in remote locations cannot afford equipment failures. CS HOH 39 Hydraulic Adapter Sleeves provide a complete mounting solution with matched lock nuts and washers that ensure perfect alignment and secure fitting even under extreme vibration and shock loads common in crushers, conveyors, and screening equipment. The precision manufacturing tolerances of our Taiwan-produced sleeves result in 45% fewer unexpected bearing failures compared to economy alternatives. Additionally, the hydraulic removal capability eliminates the risk of bearing damage during maintenance, a critical advantage when replacement parts may be days away from remote mining sites.

Manufactured from premium-grade materials at our Taiwan facility, CS HOH 39 Hydraulic Adapter Sleeves are specifically developed to enhance bearing protection and extend service life in challenging applications across steel construction, cement production, mining operations, and textile manufacturing. Available in 18 different models ranging from HOH3936 to HOH39/500, each sleeve is supplied complete with corresponding lock nuts and lock washers or lock plates, providing a comprehensive mounting solution for your specific bearing requirements. The 1:12 taper design ensures optimal fit and performance under heavy loads and extreme operating conditions.