HOH 31 Hydraulic Adapter Sleeves

HOH 3132-HOH31/500 Hydraulic adapter sleeves facilitate mounting on large bearings. An oil pump is required to inject pressurized oil. There are oil passages on the threaded side and grooves on the outer surface which can be filled with internal oil according to requirements. It is convenient for installation and the disassembly of components.

The hydraulic sleeve has the characteristics of prolonging the life of the bearing and protecting the bearing. It can be used in steel construction, cement mining, textile industry, etc. We use high-quality materials to ensure and improve the quality and life cycle of hydraulic bearing sleeves.

Model

HOH3132, HOH3134, HOH3136, HOH3138, HOH3140, HOH3144, HOH3148, HOH3152, HOH3156, HOH3160, HOH3164, HOH3168, HOH3172, HOH3176, HOH3180, HOH3184, HOH3188, HOH3192, HOH3196, HOH31/500

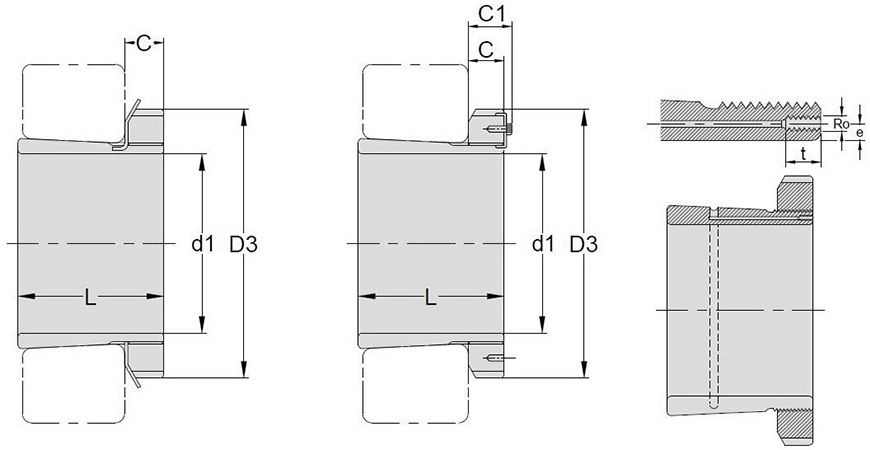

Drawing

Hydraulic Adapter Sleeves - HOH 31

TAPER 1:12

| Hydraulic Adapter Sleeve NO. | d1 | L | D3 | C | C | Ro | e | t | Lock Nut | Lock Washer & Lock Plate | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|

| H | |||||||||||

| mm | mm | mm | mm | mm | mm | mm | kg | ||||

| HOH3132 | 140 | 119 | 210 | 28 | - | M6 | 4.2 | 8 | AN32 | AW32 | 7.67 |

| HOH3134 | 150 | 122 | 220 | 29 | - | M6 | 4.2 | 8 | AN34 | AW34 | 8.38 |

| HOH3136 | 160 | 131 | 230 | 30 | - | M6 | 4.2 | 8 | AN36 | AW36 | 9.5 |

| HOH3138 | 170 | 141 | 240 | 31 | - | M6 | 4.2 | 8 | AN38 | AW38 | 10.8 |

| HOH3140 | 180 | 150 | 250 | 32 | - | M6 | 4.2 | 8 | AN40 | AW40 | 12.1 |

| HOH3144 | 200 | 161 | 280 | 35 | - | M6 | 4.2 | 8 | AN44 | AL44 | 14.7 |

| HOH3148 | 220 | 172 | 300 | 37 | - | M6 | 4.2 | 8 | AN48 | AL48 | 17.3 |

| HOH3152 | 240 | 190 | 330 | 36 | - | M6 | 4.2 | 8 | AN52 | AL52 | 22 |

| HOH3156 | 260 | 195 | 350 | 38 | - | M6 | 4.2 | 8 | AN56 | AL56 | 24.5 |

| HOH3160 | 280 | 208 | 380 | 40 | 53 | M6 | 4.2 | 8 | AN60 | AL60 | 30.2 |

| HOH3164 | 300 | 226 | 400 | 42 | 56 | M6 | 3.5 | 8 | AN64 | AL64 | 34.9 |

| HOH3168 | 320 | 254 | 440 | 55 | 72 | M6 | 3.5 | 8 | AN68 | AL68 | 49.5 |

| HOH3172 | 340 | 259 | 460 | 58 | 75 | M6 | 3.5 | 8 | AN72 | AL72 | 54.2 |

| HOH3176 | 360 | 264 | 490 | 60 | 77 | M6 | 3.5 | 8 | AN76 | AL76 | 61.7 |

| HOH3180 | 380 | 272 | 520 | 62 | 82 | M6 | 3.5 | 8 | AN80 | AL80 | 70.6 |

| HOH3184 | 400 | 304 | 540 | 70 | 90 | M6 | 3.5 | 8 | AN84 | AL84 | 84.2 |

| HOH3188 | 410 | 307 | 560 | 70 | 90 | M8 | 6.5 | 12 | AN88 | AL88 | 104 |

| HOH3192 | 430 | 326 | 580 | 75 | 95 | M8 | 6.5 | 12 | AN92 | AL92 | 116 |

| HOH3196 | 450 | 335 | 620 | 75 | 95 | M8 | 6.5 | 12 | AN96 | AL96 | 133 |

| HOH31/500 | 470 | 356 | 630 | 80 | 100 | M8 | 6.5 | 12 | AN100 | AL100 | 143 |

CS Hydraulic adapter sleeves are supplied completely with lock nuts and lock washers or lock plates.

- Download

Spec. of HOH31

Spec. of HOH3132, HOH3134, HOH3136, HOH3138, HOH3140, HOH3144, HOH3148, HOH3152, HOH3156, HOH3160, HOH3164, HOH3168, HOH3172, HOH3176, HOH3180, HOH3184,...

Download

HOH-31 Hydraulic Adapter Sleeves with Oil Injection System

Chin Sing’s HOH-31 hydraulic adapter sleeves are optimized for press-fit bearing applications requiring precision and minimal shaft damage. The oil injection system enables quick, controlled installation and removal.

Used in cement kilns, gear reducers, and mining equipment, HOH-31 sleeves reduce maintenance time and ensure alignment accuracy. These sleeves meet global quality and dimension standards, supporting consistent plant performance.

Manufactured in Taiwan with strict quality controls, Chin Sing’s HOH-31 series ensures long-term reliability for industrial operators and system builders worldwide.