AOH 32 Hydraulic Withdrawal Sleeves

AOH 32 Hydraulic Withdrawal Sleeves for metric shafts, for metric spindle. The withdrawal sleeves is one of the more popular and common used industrial sleeves. It can be used to mount bearings dismount with a tapered bore on the cylindrical seat of stepped shafts. Hydraulic bearing sleeves facilitate mounting on large bearings. An oil pump is required to inject pressurized oil. There are oil passages on the threaded side and grooves on the outer surface which can be filled with internal oil according to requirements. It is convenient for installation and the disassembly of components.

Model

AOH3232, AOH3234, AOH3236, AOH3238, AOH3240, AOH3260, AOH3264, AOH3268, AOH3272, AOH3276, AOH3280, AOH3284, AOH3288, AOH3292, AOH3296, AOH32/500

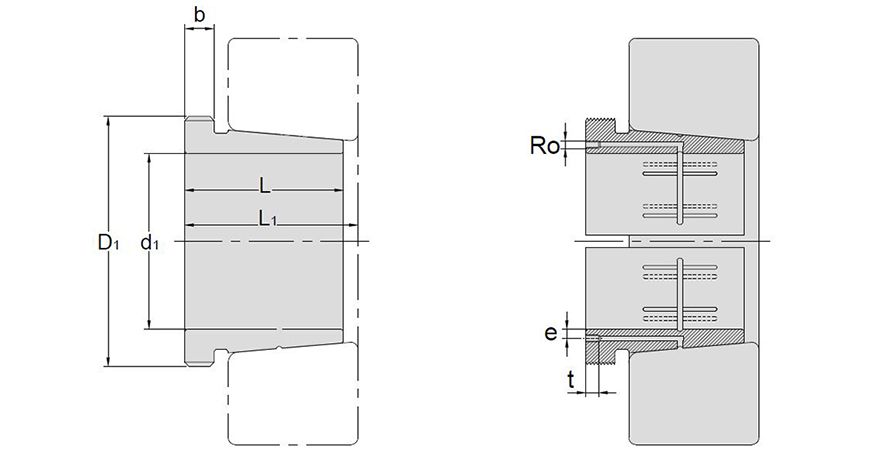

Drawing

Hydraulic Withdrawal Sleeves - AOH 32

TAPER 1:12

| Hydraulic Withdrawal Sleeves NO. | d1 | L | L | b | Ro | e | t | Thread2) | Appropriate Withdrawal Nut No. | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| D1 | ||||||||||

| mm | mm | mm | mm | mm | mm | mm | kg | |||

| AOH3232 | 150 | 124 | 130 | 20 | M6 | 4.5 | 8 | M180*3 | AN36 | 4.08 |

| AOH3234 | 160 | 134 | 140 | 24 | M6 | 4.5 | 8 | M190*3 | AN38 | 4.8 |

| AOH3236 | 170 | 140 | 146 | 24 | M6 | 4.5 | 8 | M200*3 | AN40 | 5.32 |

| AOH3238 | 180 | 145 | 152 | 25 | M6 | 4.5 | 8 | Tr210*4 | HN42 | 5.9 |

| AOH3240 | 190 | 153 | 160 | 25 | M6 | 4.5 | 8 | Tr220*4 | HN44 | 6.68 |

| AOH3260 | 280 | 228 | 236 | 34 | G1/8 | 8.5 | 12 | Tr330*5 | HN66 | 26 |

| AOH3264 | 300 | 246 | 254 | 36 | G1/8 | 8.5 | 12 | Tr350*5 | HN70 | 30.6 |

| AOH3268 | 320 | 264 | 273 | 38 | G1/8 | 8.5 | 12 | Tr370*5 | HN74 | 35.8 |

| AOH3272 | 340 | 274 | 283 | 40 | G1/8 | 8.5 | 12 | Tr400*5 | HN80 | 41.6 |

| AOH3276 | 360 | 284 | 294 | 42 | G1/8 | 8.5 | 12 | Tr420*5 | HN84 | 46.3 |

| AOH3280 | 380 | 302 | 312 | 44 | G1/8 | 8.5 | 12 | Tr440*5 | HN88 | 52.5 |

| AOH3284 | 400 | 321 | 331 | 46 | G1/8 | 8.5 | 12 | Tr460*5 | HN92 | 59.7 |

| AOH3288 | 420 | 330 | 341 | 48 | G1/8 | 8.5 | 12 | Tr480*5 | HN96 | 64.8 |

| AOH3292 | 440 | 349 | 360 | 50 | G1/8 | 8.5 | 12 | Tr510*6 | HN102 | 75.2 |

| AOH3296 | 460 | 364 | 376 | 52 | G1/8 | 8.5 | 12 | Tr530*6 | HN106 | 83.1 |

| AOH32/500 | 480 | 393 | 405 | 54 | G1/8 | 8.5 | 12 | Tr550*6 | HN110 | 94.7 |

⊚ Dimension L1 decreases as the Hydraulic withdrawal sleeve is driven in during mounting.

⊚ M means metric thread. Tr means 30°, trapezoid thread and the digits are outside diameter of thread and pitch.

- Download

Spec. of AOH32

Spec. of AOH3232, AOH3234, AOH3236, AOH3238, AOH3240, AOH3260, AOH3264, AOH3268, AOH3272, AOH3276, AOH3280, AOH3284, AOH3288, AOH3292, AOH3296, AOH32/500

Download

AOH-32 Hydraulic Withdrawal Sleeves for High-Performance Systems

Chin Sing’s AOH-32 sleeves are designed for hydraulic bearing dismounting in large-scale industrial machinery. With precise tapering and oil channels, these sleeves reduce the risk of misalignment or component wear during removal.

Commonly used in paper mills, turbines, and mechanical presses, AOH-32 sleeves help streamline maintenance procedures while safeguarding your equipment. Machined to ISO tolerances for a perfect fit every time.

Upgrade your service routines with AOH-32 sleeves—trusted for high-pressure applications and proven dismounting performance.