AOH 31 Hydraulic Withdrawal Sleeves

AOH 31 Hydraulic Withdrawal Sleeves for metric shafts, for metric spindle. The withdrawal sleeves is one of the more popular and common used industrial sleeves. It can be used to mount bearings dismount with a tapered bore on the cylindrical seat of stepped shafts. Hydraulic bearing sleeves facilitate mounting on large bearings. An oil pump is required to inject pressurized oil. There are oil passages on the threaded side and grooves on the outer surface which can be filled with internal oil according to requirements. It is convenient for installation and the disassembly of components.

Model

AOH3132, AOH3134, AOH3136, AOH3138, AOH3140, AOH3144, AOH3148, AOH3152, AOH3156, AOH3160, AOH3164, AOH3168, AOH3172, AOH3176, AOH3180, AOH3184, AOH3188, AOH3192, AOH3196, AOH31/500

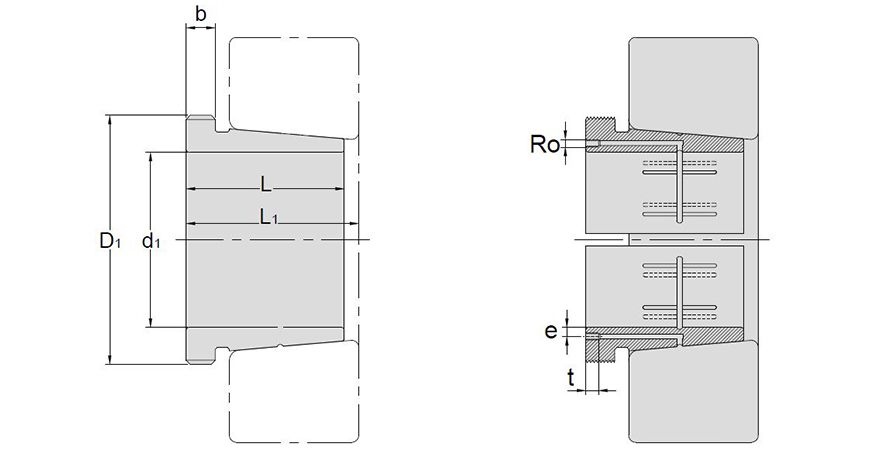

Drawing

Hydraulic Withdrawal Sleeves - AOH 31

TAPER 1:12

| Hydraulic Withdrawal Sleeves NO. | d1 | L | L | b | Ro | e | t | Thread2) | Appropriate Withdrawal Nut No. | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| D1 | ||||||||||

| mm | mm | mm | mm | mm | mm | mm | kg | |||

| AOH3132 | 150 | 103 | 108 | 16 | M6 | 4.5 | 8 | M180*3 | AN36 | 3.21 |

| AOH3134 | 160 | 104 | 109 | 16 | M6 | 4.5 | 8 | M190*3 | AN38 | 3.4 |

| AOH3136 | 170 | 116 | 122 | 19 | M6 | 4.5 | 8 | M200*3 | AN40 | 4.22 |

| AOH3138 | 180 | 125 | 131 | 20 | M6 | 4.5 | 8 | Tr210*4 | HN42 | 4.89 |

| AOH3140 | 190 | 134 | 140 | 21 | M6 | 4.5 | 8 | Tr220*4 | HN44 | 5.49 |

| AOH3144 | 200 | 145 | 151 | 23 | G1/8 | 8.5 | 12 | Tr240*4 | HN48 | 10.4 |

| AOH3148 | 220 | 154 | 161 | 25 | G1/8 | 8.5 | 12 | Tr260*4 | HN52 | 12 |

| AOH3152 | 240 | 172 | 179 | 26 | G1/8 | 8.5 | 12 | Tr290*4 | HN58 | 16.2 |

| AOH3156 | 260 | 175 | 183 | 28 | G1/8 | 8.5 | 12 | Tr310*4 | HN62 | 17.5 |

| AOH3160 | 280 | 192 | 200 | 30 | G1/8 | 8.5 | 12 | Tr330*5 | HN66 | 20.8 |

| AOH3164 | 300 | 209 | 217 | 31 | G1/8 | 8.5 | 12 | Tr350*5 | HN70 | 24.5 |

| AOH3168 | 320 | 225 | 234 | 33 | G1/8 | 8.5 | 12 | Tr370*5 | HN74 | 29 |

| AOH3172 | 340 | 229 | 238 | 35 | G1/8 | 8.5 | 12 | Tr400*5 | HN80 | 33 |

| AOH3176 | 360 | 232 | 242 | 36 | G1/8 | 8.5 | 12 | Tr420*5 | HN84 | 35.7 |

| AOH3180 | 380 | 240 | 250 | 38 | G1/8 | 8.5 | 12 | Tr440*5 | HN88 | 39.5 |

| AOH3184 | 400 | 266 | 276 | 40 | G1/8 | 8.5 | 12 | Tr460*5 | HN92 | 46.5 |

| AOH3188 | 420 | 270 | 281 | 42 | G1/8 | 8.5 | 12 | Tr480*5 | HN96 | 49.8 |

| AOH3192 | 440 | 285 | 296 | 43 | G1/8 | 8.5 | 12 | Tr510*6 | HN102 | 57.9 |

| AOH3196 | 460 | 295 | 307 | 45 | G1/8 | 8.5 | 12 | Tr530*6 | HN106 | 63.1 |

| AOH 31/500 | 480 | 313 | 325 | 47 | G1/8 | 8.5 | 12 | Tr550*6 | HN110 | 70.9 |

⊚ Dimension L1 decreases as the Hydraulic withdrawal sleeve is driven in during mounting.

⊚ M means metric thread. Tr means 30°, trapezoid thread and the digits are outside diameter of thread and pitch.

- Download

Spec. of AOH31

Spec. of AOH3132, AOH3134, AOH3136, AOH3138, AOH3140, AOH3144, AOH3148, AOH3152, AOH3156, AOH3160, AOH3164, AOH3168, AOH3172, AOH3176, AOH3180, AOH3184,...

Download

AOH-31 Hydraulic Withdrawal Sleeves for Shaft and Bearing Safety

The AOH-31 hydraulic withdrawal sleeves from Chin Sing provide safe and efficient dismounting of large bearings using an oil injection system. These sleeves reduce mechanical strain and protect shaft integrity in high-demand settings.

Used in mining crushers, rolling lines, and drive units, AOH-31 sleeves offer smooth removal and long-term operational reliability. They conform to ISO specs and integrate easily into most European and Asian bearing setups.

For precision-driven disassembly and minimized downtime, AOH-31 hydraulic sleeves deliver best-in-class performance.