AOH 23 Hydraulic Withdrawal Sleeves

AOH 23 Hydraulic Withdrawal Sleeves for metric shafts, for metric spindle. The withdrawal sleeves is one of the more popular and common used industrial sleeves. It can be used to mount bearings dismount with a tapered bore on the cylindrical seat of stepped shafts.

Hydraulic bearing sleeves facilitate mounting on large bearings. An oil pump is required to inject pressurized oil. There are oil passages on the threaded side and grooves on the outer surface which can be filled with internal oil according to requirements. It is convenient for installation and the disassembly of components.

Model

AOH2332, AOH2334, AOH2336, AOH2338, AOH2340, AOH2344, AOH2348, AOH2352, AOH2356

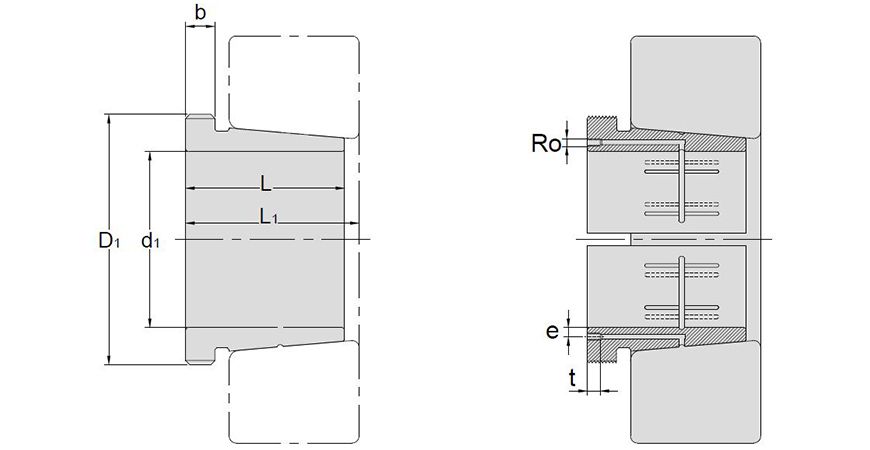

Drawing

Hydraulic Withdrawal Sleeves - AOH 23

TAPER 1:12

| Hydraulic Withdrawal Sleeves NO. | d1 | L | L | b | Ro | e | t | Thread2) | Appropriate Withdrawal Nut No. | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| D1 | ||||||||||

| mm | mm | mm | mm | mm | mm | mm | kg | |||

| AOH2332 | 150 | 140 | 146 | 24 | M6 | 4.5 | 8 | M180*3 | AN36 | 4.72 |

| AOH2334 | 160 | 146 | 152 | 24 | M6 | 4.5 | 8 | M190*3 | AN38 | 5.25 |

| AOH2336 | 170 | 154 | 160 | 26 | M6 | 4.5 | 8 | M200*3 | AN40 | 5.83 |

| AOH2338 | 180 | 160 | 167 | 26 | M6 | 4.5 | 8 | Tr210*4 | HN42 | 6.63 |

| AOH2340 | 190 | 170 | 177 | 30 | M6 | 4.5 | 8 | Tr220*4 | HN44 | 7.54 |

| AOH2344 | 200 | 181 | 189 | 30 | G1/8 | 8.5 | 12 | Tr240*4 | HN48 | 13.5 |

| AOH2348 | 220 | 189 | 197 | 30 | G1/8 | 8.5 | 12 | Tr260*4 | HN52 | 15.5 |

| AOH2352 | 240 | 205 | 213 | 30 | G1/8 | 8.5 | 12 | Tr290*4 | HN58 | 19.6 |

| AOH2356 | 260 | 212 | 220 | 30 | G1/8 | 8.5 | 12 | Tr310*5 | HN62 | 21.6 |

⊚ Dimension L1 decreases as the Hydraulic withdrawal sleeve is driven in during mounting.

⊚ M means metric thread. Tr means 30°, trapezoid thread and the digits are outside diameter of thread and pitch.

- Download

Spec. of AOH23

Spec. of AOH2332, AOH2334, AOH2336, AOH2338, AOH2340, AOH2344, AOH2348, AOH2352, AOH2356

Download

AOH-23 Hydraulic Withdrawal Sleeves for Quick and Safe Bearing Removal

The AOH-23 hydraulic withdrawal sleeves from Chin Sing simplify bearing dismounting by using controlled hydraulic pressure. This oil-injection method prevents shaft damage and speeds up maintenance in large industrial systems.

Perfect for wind turbines, steel mill rolls, and rotary machinery, AOH-23 sleeves ensure consistent fit and safe disassembly. Each sleeve features standardized oil ducts and thread interfaces for global compatibility.

Choose Chin Sing’s AOH-23 sleeves to boost service efficiency and reduce mechanical stress during bearing removal in critical operations.