AH 39 Withdrawal Sleeves

AH 39 Withdrawal Sleeves can mount a tapered bore bearing on a round stepped shaft, which is one of the more popular and commonly used industrial sleeves. Generally, the withdrawal sleeve was pressed into a bearing inner bore to fix it on the shaft through a fiber web or endplate. For larger bearings, when it was pressed against the bearing bore, a larger force is required to overcome the friction of the mating surface. Hydraulic installation can simplify this process by a withdrawal sleeve.

Model

AH3936, AH3938, AH3940, AH3944, AH3948, AH3952, AH3956, AH3960, AH3964, AH3968, AH3972, AH3976, AH3980, AH3984, AH3988, AH3992, AH3996, AH39/500

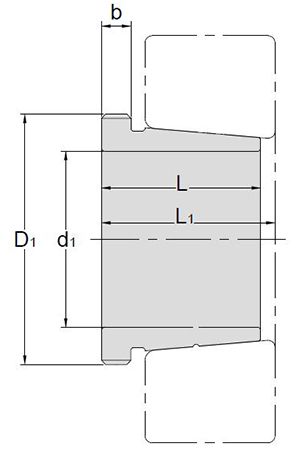

Drawing

Withdrawal Sleeves - AH 39

TAPER 1:12

| Withdrawal Sleeves NO. | d1 | L | L | b | Thread2) | Appropriate Withdrawal Nut No. | Weight |

|---|---|---|---|---|---|---|---|

| D1 | |||||||

| mm | mm | mm | mm | mm | kg | ||

| AH3936 | 170 | 66 | 71 | 13 | M190*3 | AN38 | 1.91 |

| AH3938 | 180 | 66 | 71 | 13 | M200*3 | AN40 | 2.02 |

| AH3940 | 190 | 77 | 83 | 16 | Tr210*4 | HN42 | 2.62 |

| AH3944 | 200 | 77 | 83 | 16 | Tr230*4 | HN46 | 4.83 |

| AH3948 | 220 | 77 | 83 | 16 | Tr250*4 | HN50 | 5.29 |

| AH3952 | 240 | 94 | 100 | 18 | Tr270*4 | HN54 | 7.06 |

| AH3956 | 260 | 94 | 100 | 18 | Tr290*4 | HN58 | 7.7 |

| AH3960 | 280 | 112 | 119 | 21 | Tr310*5 | HN62 | 10.1 |

| AH3964 | 300 | 112 | 119 | 21 | Tr330*5 | HN66 | 10.8 |

| AH3968 | 320 | 112 | 119 | 21 | Tr360*5 | HNL72 | 12.4 |

| AH3972 | 340 | 112 | 119 | 21 | Tr380*5 | HNL76 | 13.1 |

| AH3976 | 360 | 130 | 138 | 22 | Tr400*5 | HNL80 | 15.9 |

| AH3980 | 380 | 130 | 138 | 22 | Tr420*5 | HNL84 | 17.2 |

| AH3984 | 400 | 130 | 138 | 22 | Tr440*5 | HNL88 | 18.1 |

| AH3988 | 420 | 145 | 153 | 25 | Tr460*5 | HNL92 | 21.5 |

| AH3992 | 440 | 145 | 153 | 25 | Tr480*5 | HNL96 | 22.5 |

| AH3996 | 460 | 158 | 167 | 28 | Tr500*5 | HNL100 | 26 |

| AH39/500 | 480 | 162 | 172 | 32 | Tr520*6 | HNL104 | 27.7 |

⊚ Dimension L1 decreases as the withdrawal sleeve is driven in during mounting.

⊚ M means metric thread. Tr means 30°, trapezoid thread and the digits are outside diameter of thread and pitch.

- Download

Spec. of AH39

Spec. of AH3936, AH3938, AH3940, AH3944, AH3948, AH3952, AH3956, AH3960, AH3964, AH3968, AH3972, AH3976, AH3980, AH3984, AH3988, AH3992, AH3996, AH39/500

Download

AH39 Withdrawal Sleeves for Large Shaft and Bearing Systems

Designed for large-scale industrial equipment, Chin Sing’s AH39 withdrawal sleeves simplify bearing removal while protecting shaft surfaces and equipment tolerances. These sleeves are ideal for systems with frequent maintenance schedules.

Common in marine propulsion systems, turbines, and heavy processing lines, AH39 sleeves provide a secure taper fit and easy compatibility with standard withdrawal hardware. Precision-manufactured for ISO compliance.

Upgrade your dismounting efficiency with AH39 withdrawal sleeves, delivering long-lasting strength and alignment accuracy in high-capacity systems.