AH 3 Withdrawal Sleeves

AH 3 Withdrawal Sleeves can mount a tapered bore bearing on a round stepped shaft, which is one of the more popular and commonly used industrial sleeves. Generally, the withdrawal sleeves are pressed into a bearing inner bore to fix it on the shaft through a fiber web or endplate. For larger bearings, when it is pressed against the bearing bore, a larger force is required to overcome the friction of the mating surface. Hydraulic installation can simplify this process by a withdrawal sleeve.

Model

AH308, AH309, AHX310, AHX311, AHX312, AH313, AH314, AH315, AH316, AHX317, AH318, AHX319, AHX320, AHX322

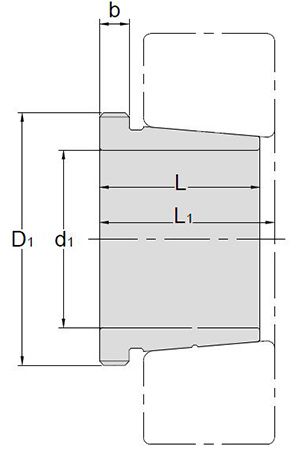

Drawing

Withdrawal Sleeves - AH 3

TAPER 1:12

| Withdrawal Sleeves NO. | d1 | L | L | b | Thread2) | Appropriate Withdrawal Nut No. | Weight |

|---|---|---|---|---|---|---|---|

| D1 | |||||||

| mm | mm | mm | mm | mm | kg | ||

| AH308 | 35 | 29 | 32 | 6 | M45*1.5 | AN09 | 0.09 |

| AH309 | 40 | 31 | 34 | 6 | M50*1.5 | AN10 | 0.109 |

| AHX310 | 45 | 35 | 38 | 7 | M55*2 | AN11 | 0.137 |

| AHX311 | 50 | 37 | 40 | 7 | M60*2 | AN12 | 0.161 |

| AHX312 | 55 | 40 | 43 | 8 | M65*2 | AN13 | 0.189 |

| AH313 | 60 | 42 | 45 | 8 | M75*2 | AN15 | 0.253 |

| AH314 | 65 | 43 | 47 | 8 | M80*2 | AN16 | 0.28 |

| AH315 | 70 | 45 | 49 | 8 | M85*2 | AN17 | 0.313 |

| AH316 | 75 | 48 | 52 | 8 | M90*2 | AN18 | 0.365 |

| AHX317 | 80 | 52 | 56 | 9 | M95*2 | AN19 | 0.429 |

| AHX318 | 85 | 53 | 57 | 9 | M100*2 | AN20 | 0.461 |

| AHX319 | 90 | 57 | 61 | 10 | M105*2 | AN21 | 0.532 |

| AHX320 | 95 | 59 | 63 | 10 | M110*2 | AN22 | 0.582 |

| AHX322 | 105 | 63 | 67 | 12 | M120*2 | AN24 | 0.663 |

⊚ Dimension L1 decreases as the withdrawal sleeve is driven in during mounting.

⊚ M means metric thread.

- Download

Spec. of AH3

Spec. of AH308, AH309, AHX310, AHX311, AHX312, AH313, AH314, AH315, AH316, AHX317, AH318, AHX319, AHX320, AHX322

Download

AH3 Withdrawal Sleeves for Secure and Simple Bearing Dismounting

Chin Sing’s AH3 withdrawal sleeves allow for safe and efficient dismounting of tapered bore bearings from cylindrical shafts. Designed for ISO standard compatibility, they eliminate the need for complex removal tools or damaging force.

These sleeves are ideal for maintenance and replacement in heavy equipment such as motors, crushers, and pumps. Their precision-tapered body and threaded end ensure smooth withdrawal and minimal shaft wear.

With proven performance across steel, energy, and processing sectors, AH3 sleeves are trusted by OEMs and MROs worldwide for reliability and convenience.